-

Exterior

- Canopies

- Roller Shutters

- Tonneau Covers

- Bed Mats & Liners

- Cargo Organizers & Slides

- Tailgate Dampers

- Kung-kemper

- Power bumpers

- Protection of the bottom

- Tarcopes

- The thresholds

- Kangaroo and arcs

- Expanders and protection of arches

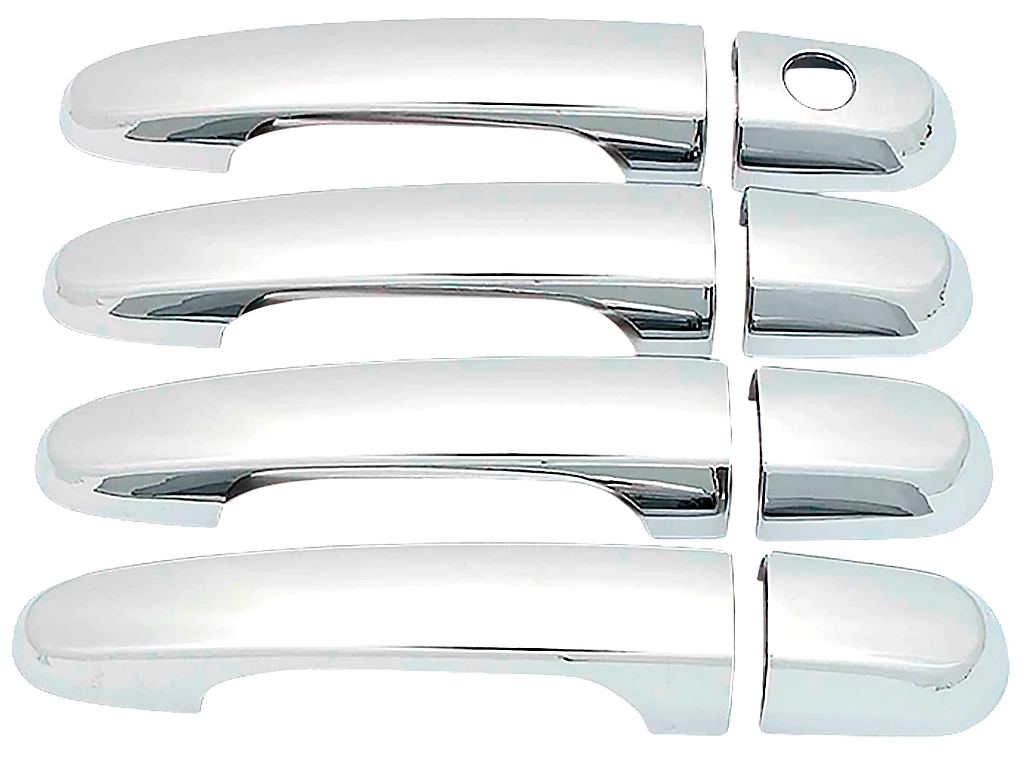

- Chromium lining

- Brizhoviks

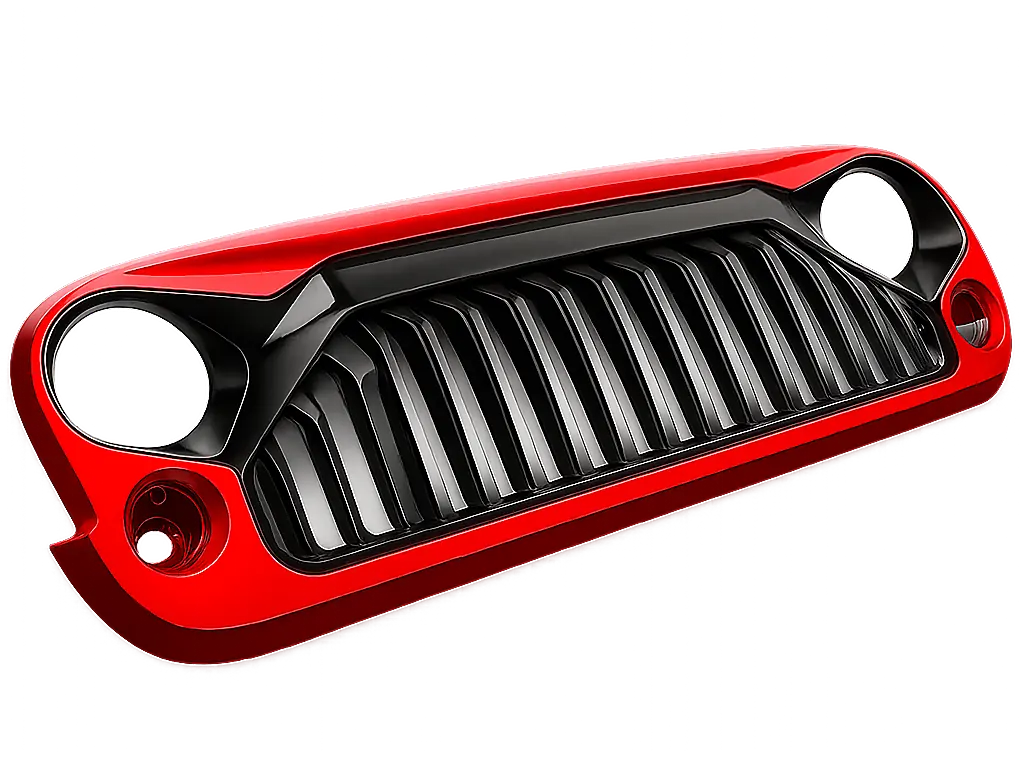

- Stylization of the car

- Deflectors

- Winches

- Rigging

- Dumps

- Road mixture spreaders

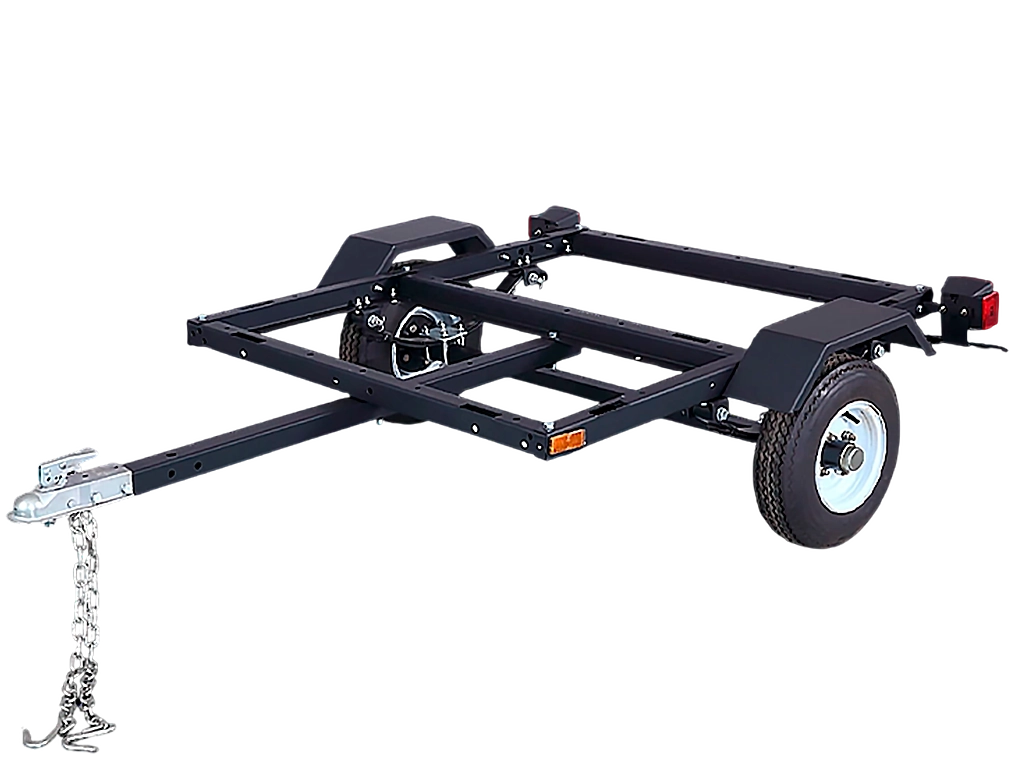

- Trailer

- Spare parts for trailers

- Boxes and baskets on the roof

- The trunk

- Snorkel

- Fuel tanks

- Automatic tents

- SUV tires

- Disks for SUVs

- For ATVs

- Shockizer of hood

- Trunk struts

- Soft roof, awning, racks

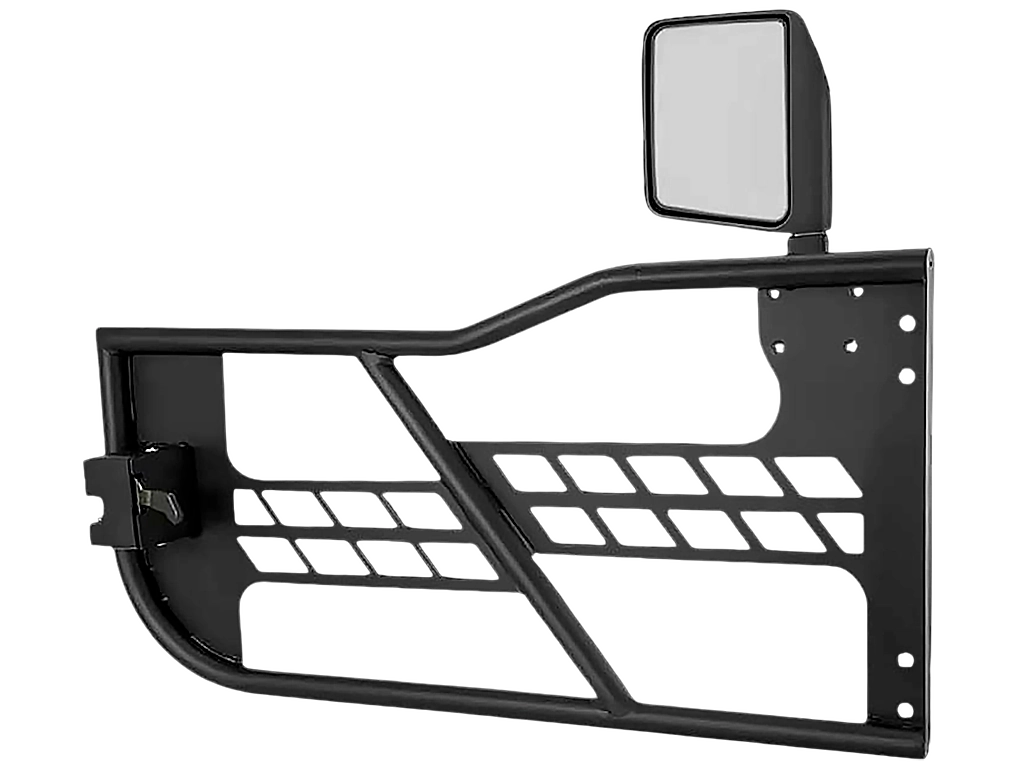

- Doors and mirror

-

Heavy Duty Parts

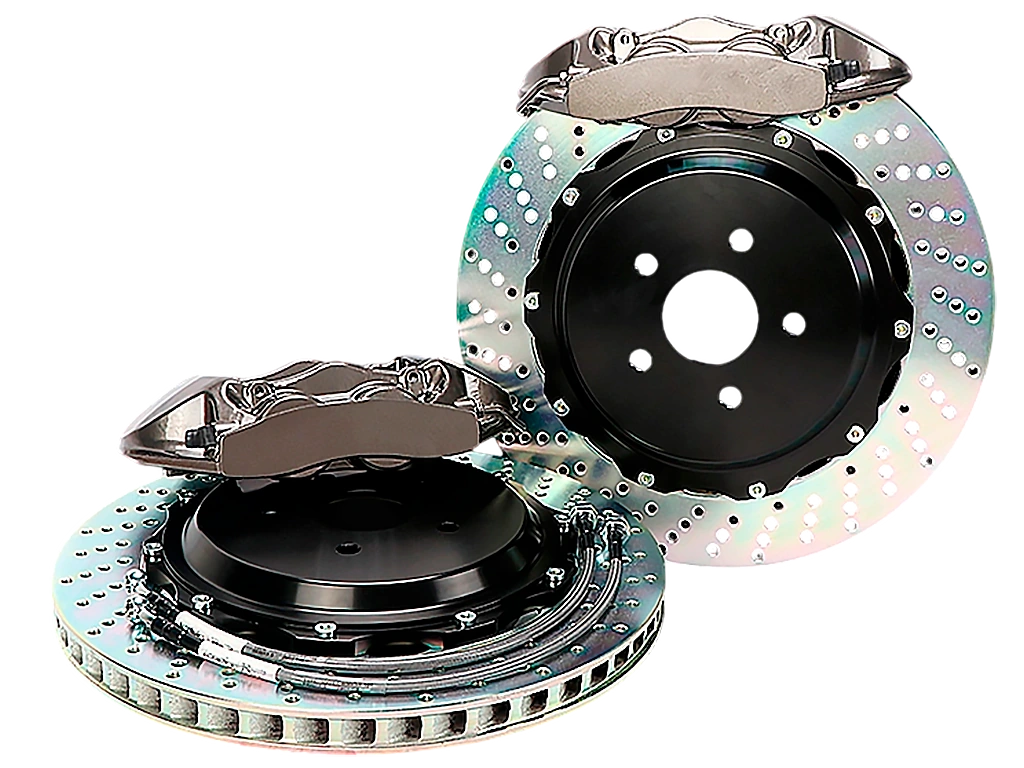

- Brake systems

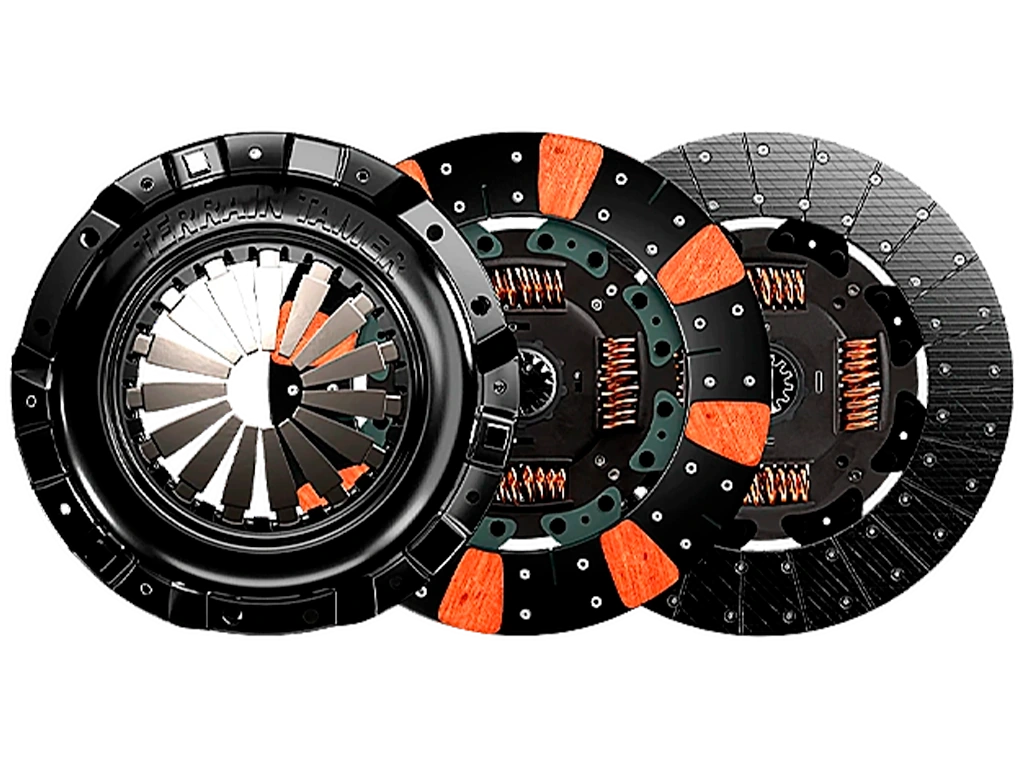

- Increased clutch

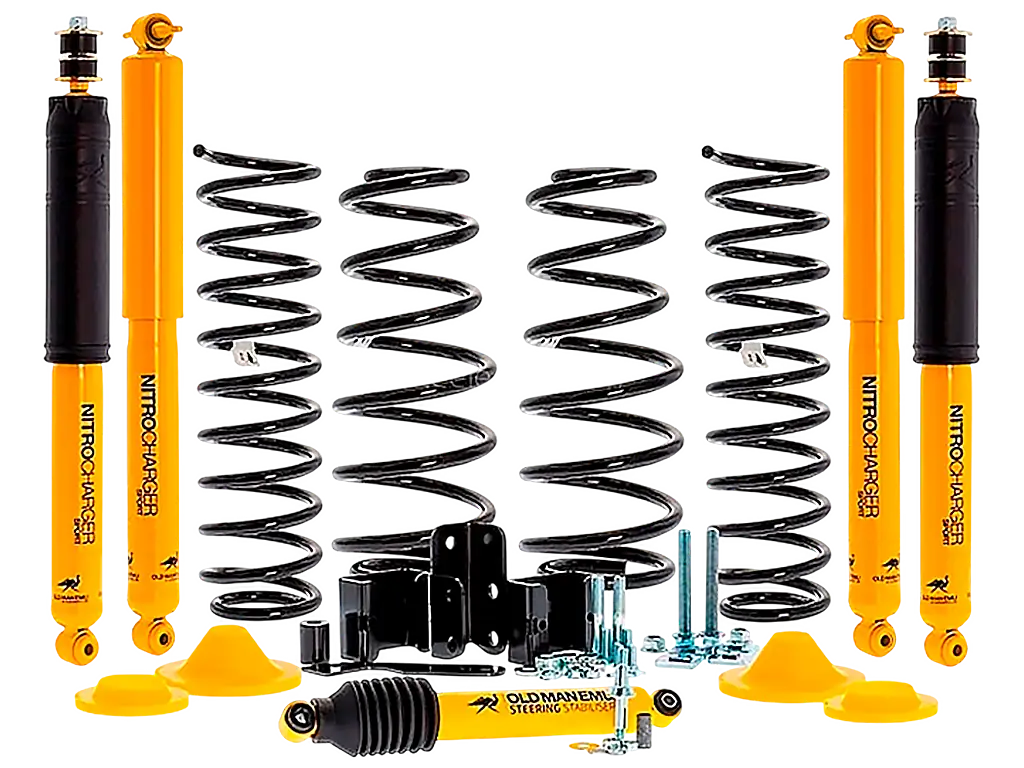

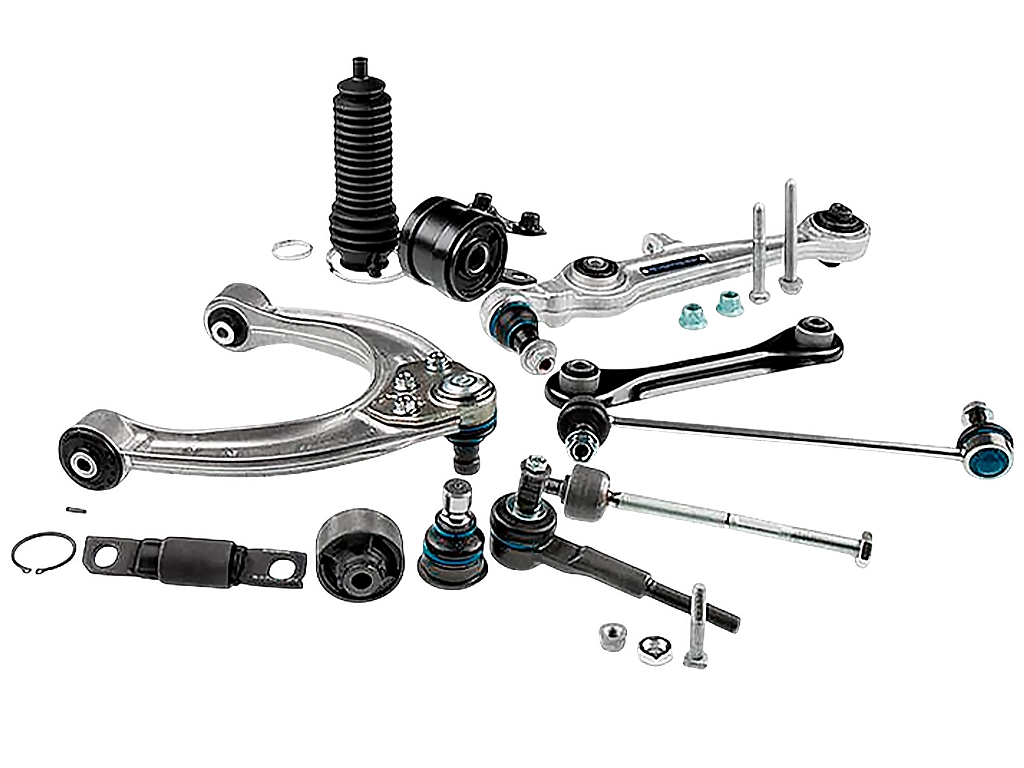

- Suspension Kits

- Shock absorbers

- Shock absorber racks

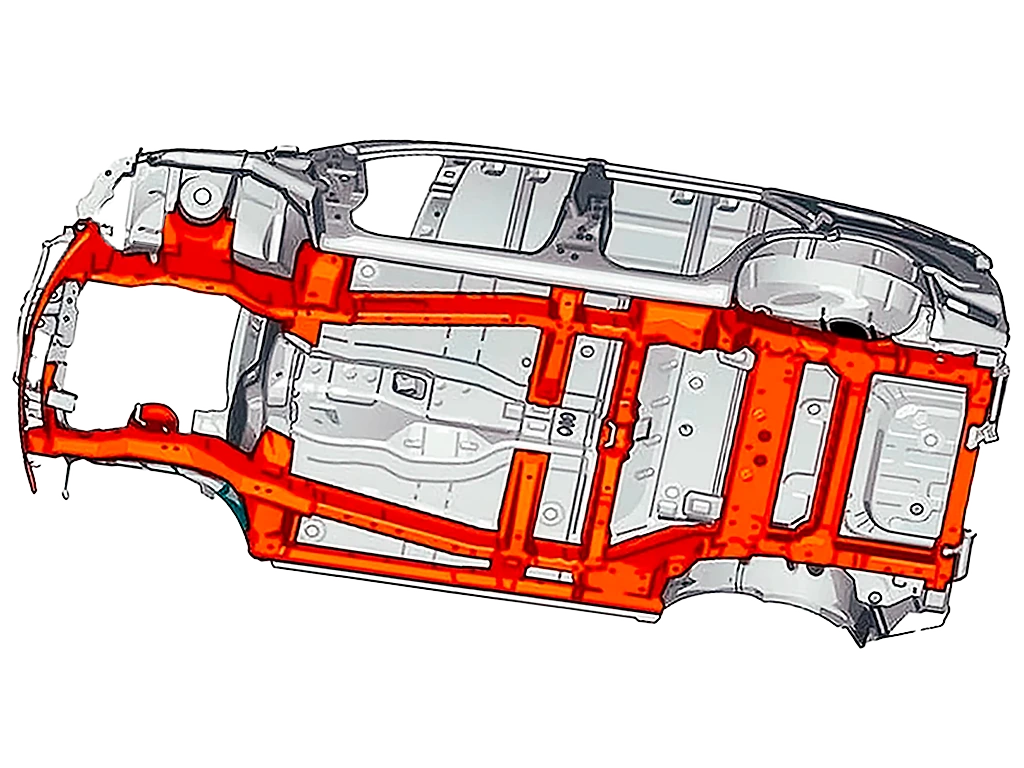

- Spars

- Damper

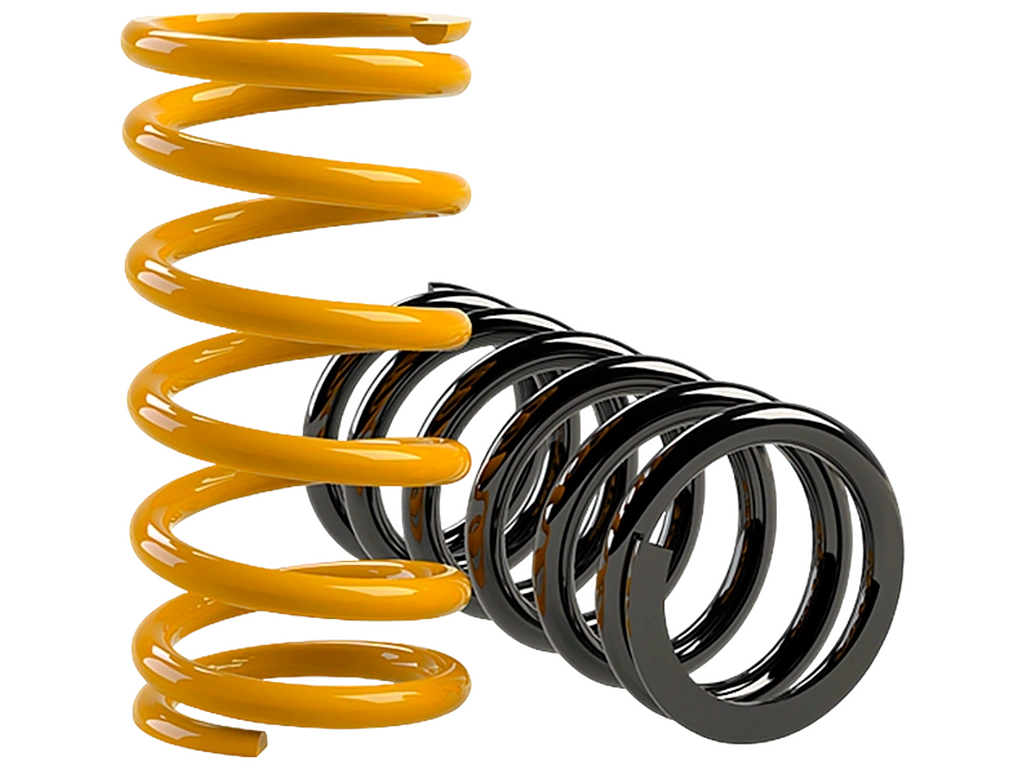

- Springs

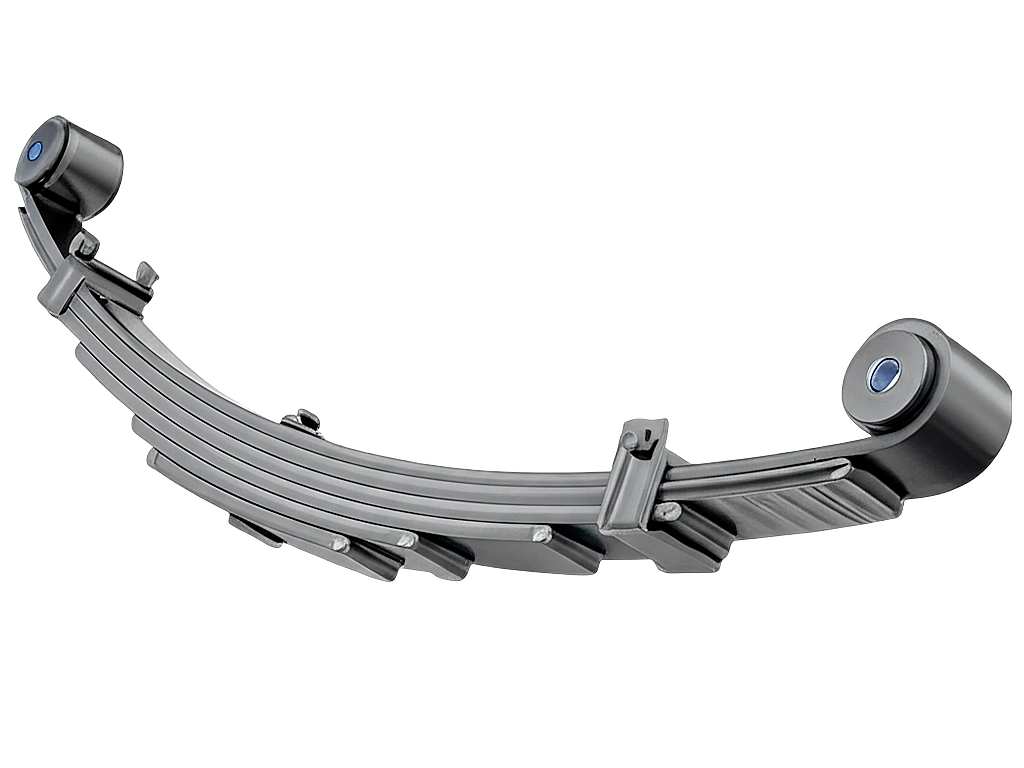

- Springs

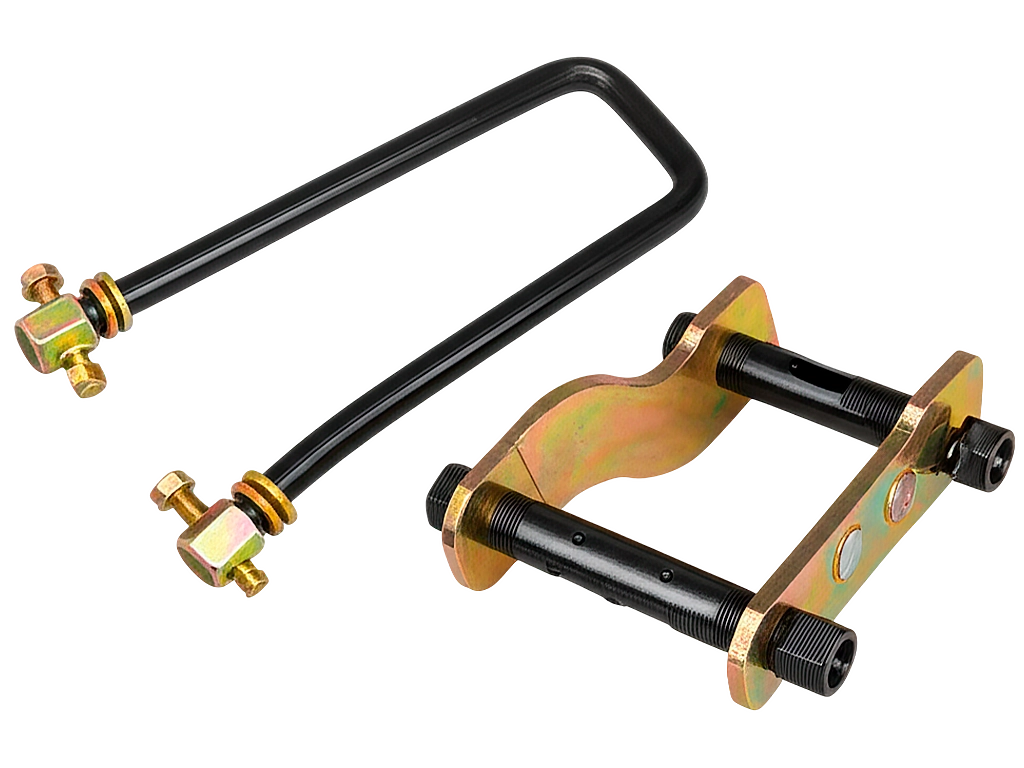

- Earrings and fastening springs

- Springs

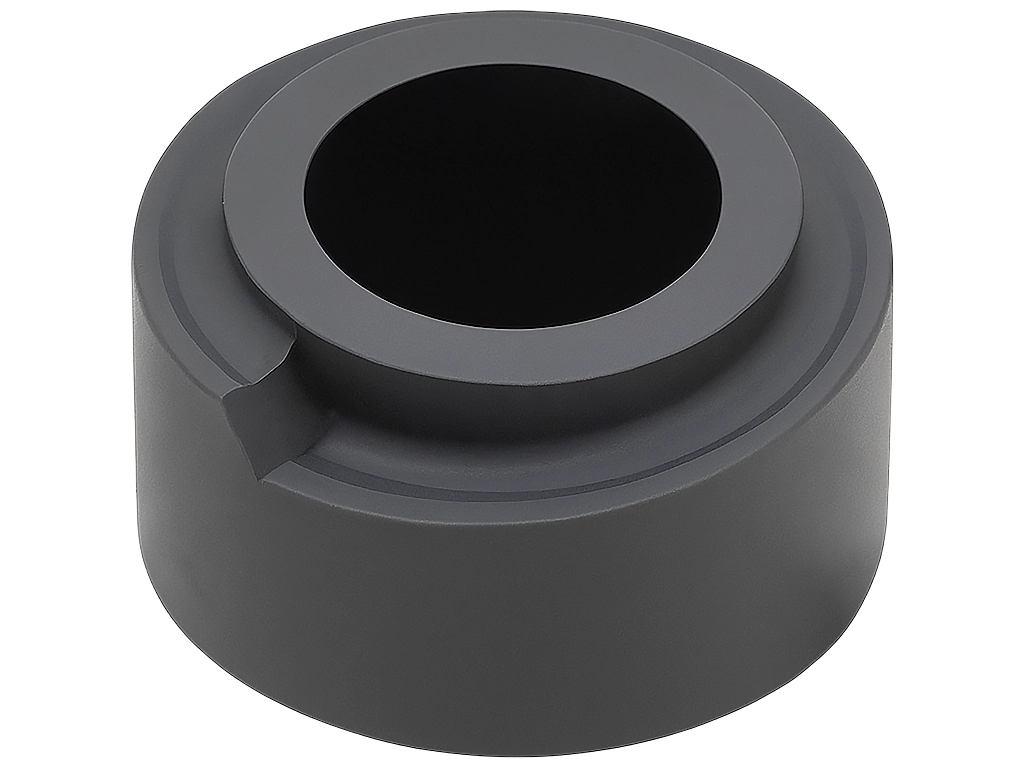

- Springs under springs

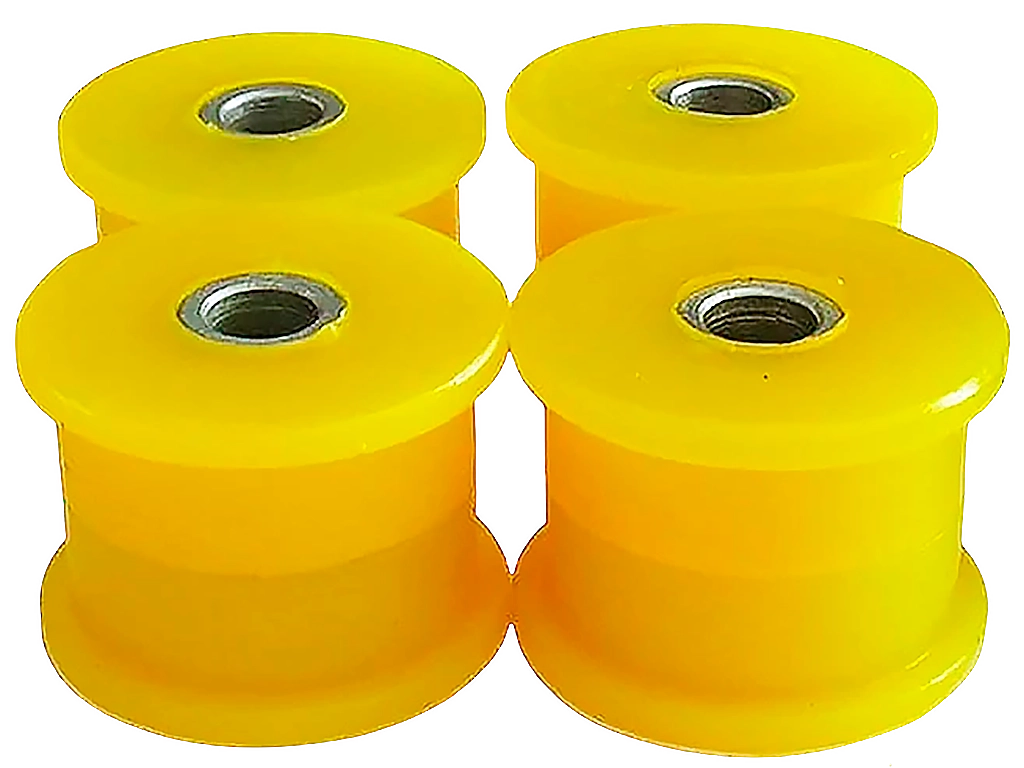

- Silent blocks and more

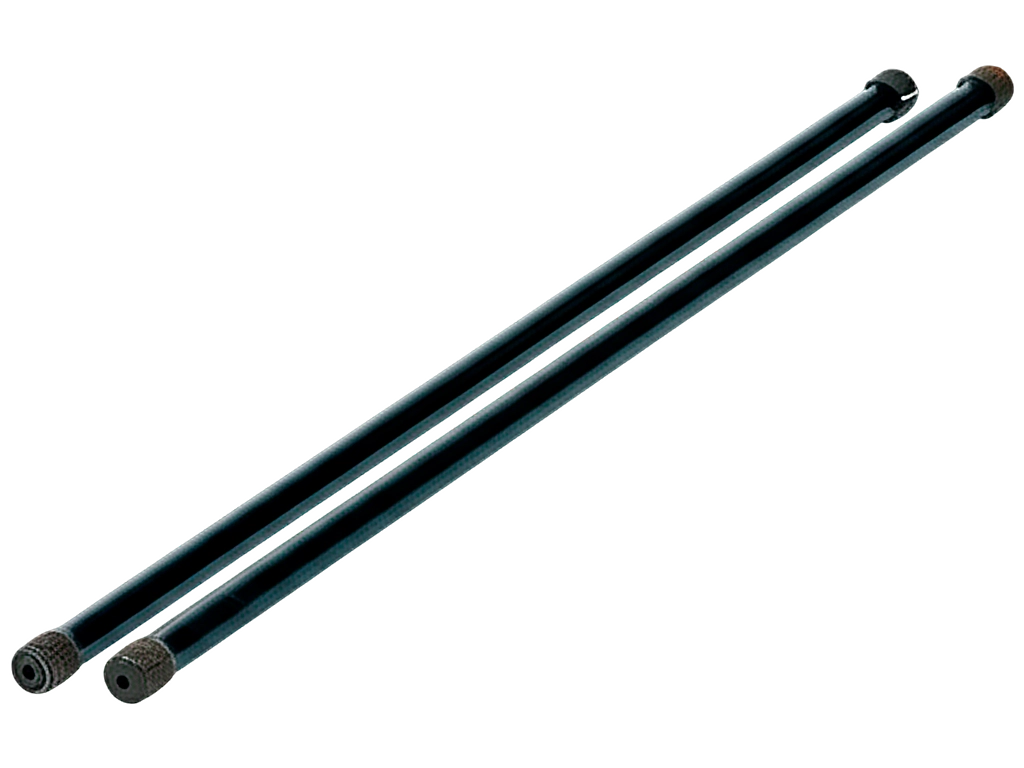

- Torsions

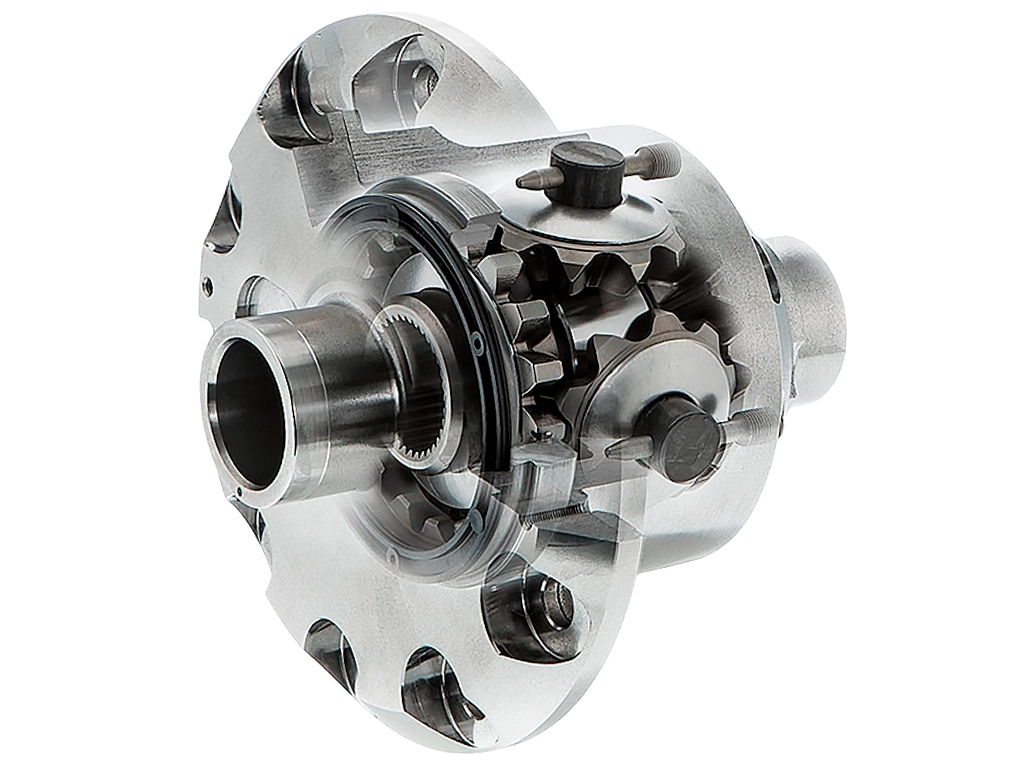

- Differential

- Wheel couplings (hubs)

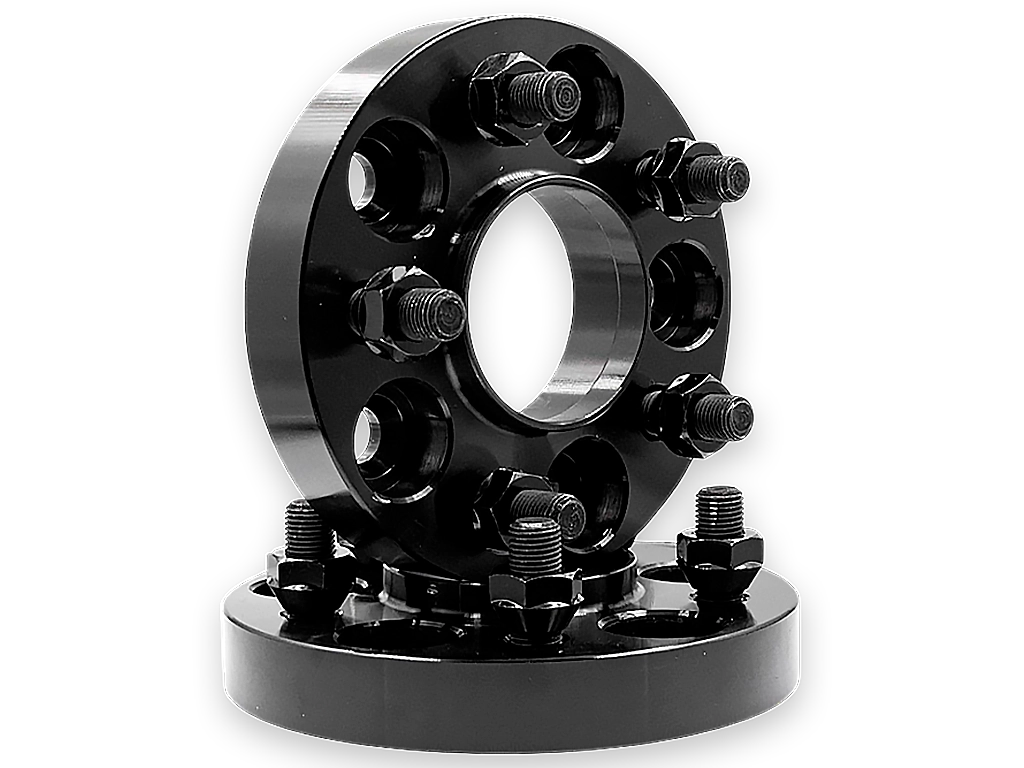

- Wheel spacing

- Car bearings

- Panara thrust

- Side thrust

- Steering

- Control levers

- Stabilizers

- Drive shafts

- Generators

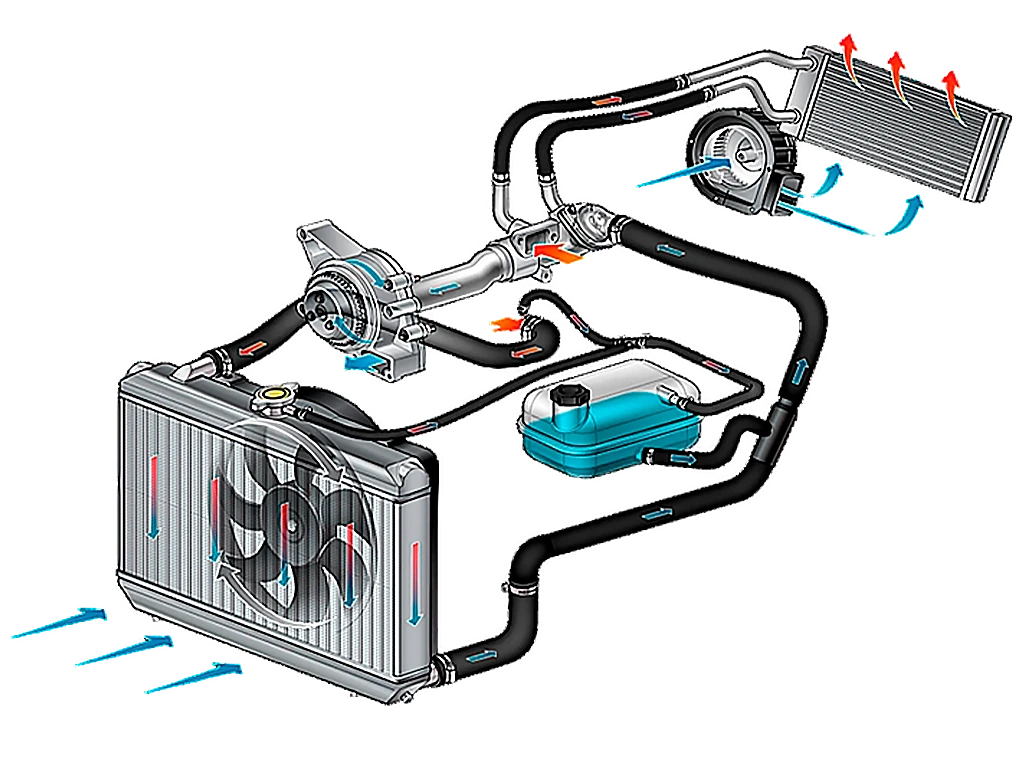

- The engine cooling system

- Starters

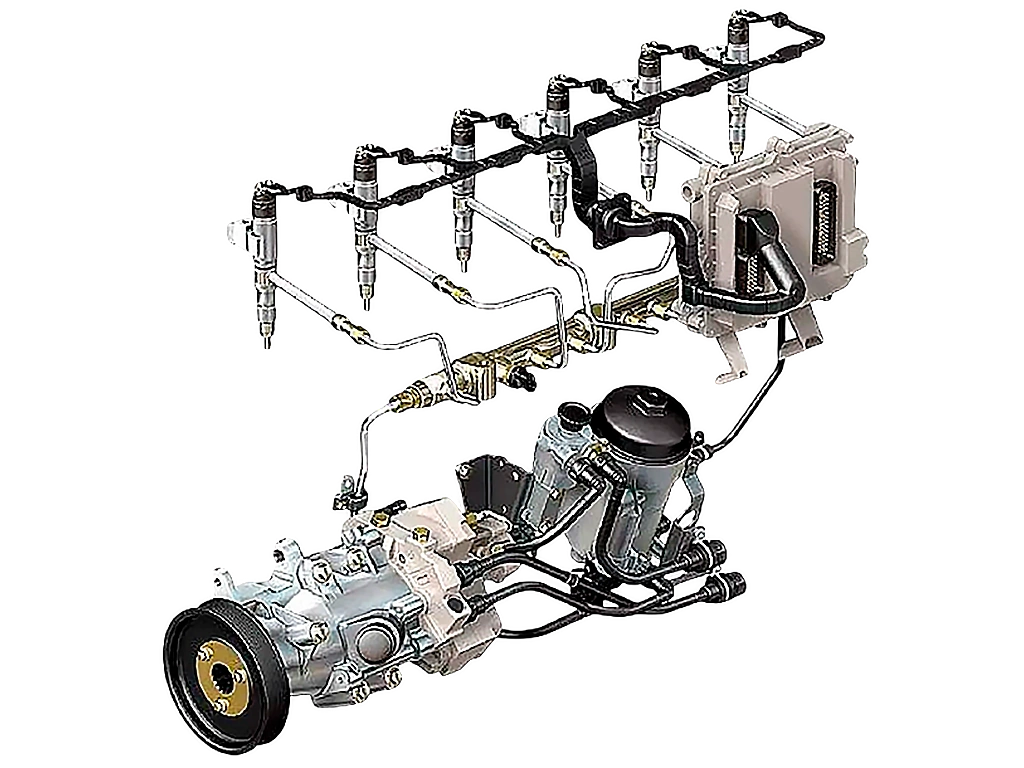

- Fuel system

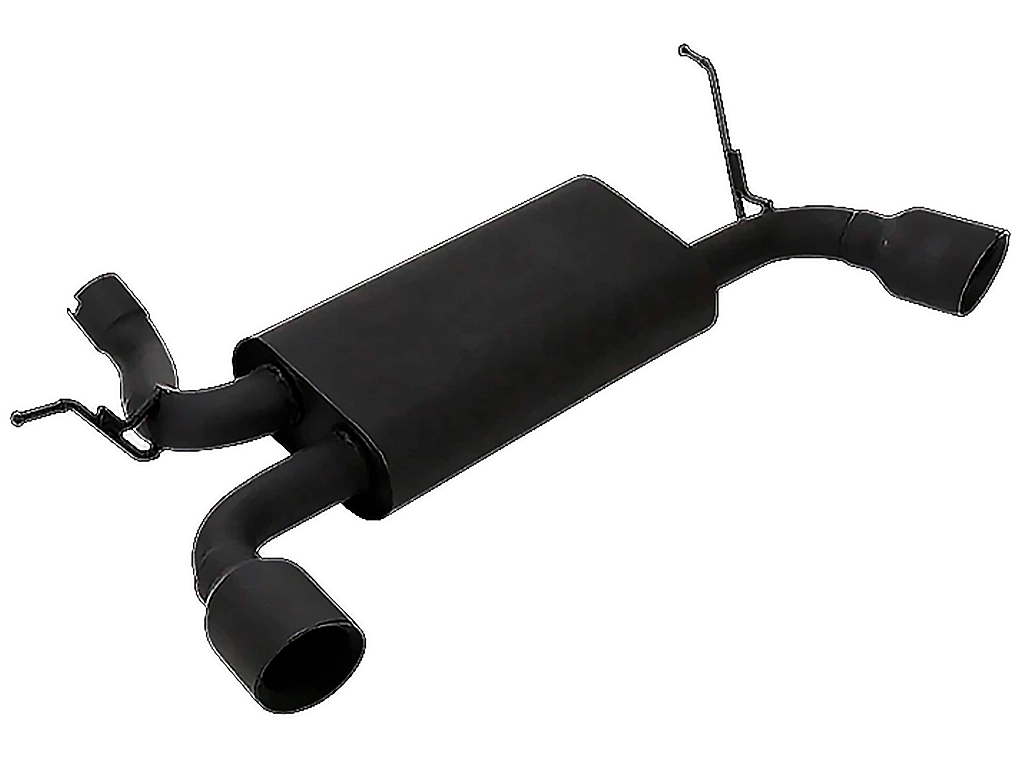

- The system of inlet and release

- Other suspension spare parts

- Lights

- Interior

- Accessories

-

Electronics

- Charging stations

- Solar panels

- Electric Vehicles

- Radios and radio stations

- Rear -view chambers

- Ajax

- Power Bank)

- Quadcopters

- Inverters (voltage converters)

- Voltage stabilizers

- Car chargers

- Parkronics

- Registrars

- Action cameras

- Generator

- Batteries

- Lanterns

- Uninterrupted power sources (UPS)

- Multimedia systems

- Jumper cables

- Turbofans

- Signals

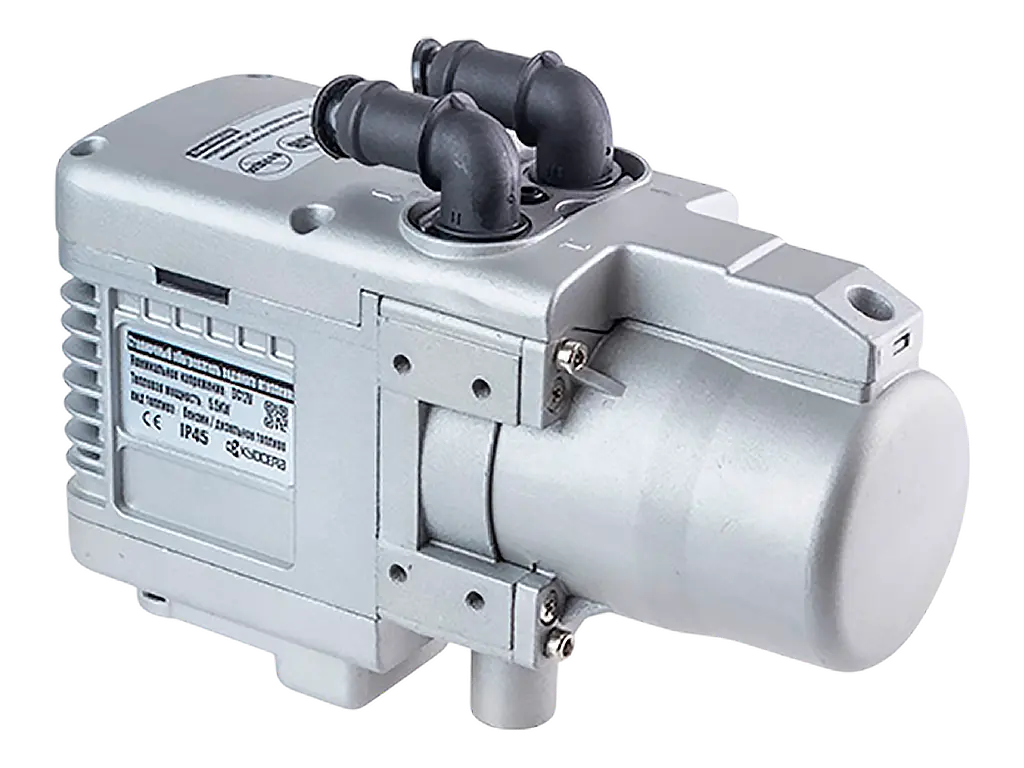

- Engine preheaters

- Autonomous heaters

- Fans, fan heaters

- Automobile alarm

-

Tourism

- For the military

- Grilled

- Picnic sets

- Recreation furniture

- Auto -holders

- Tourist utensils

- Kung-kemper

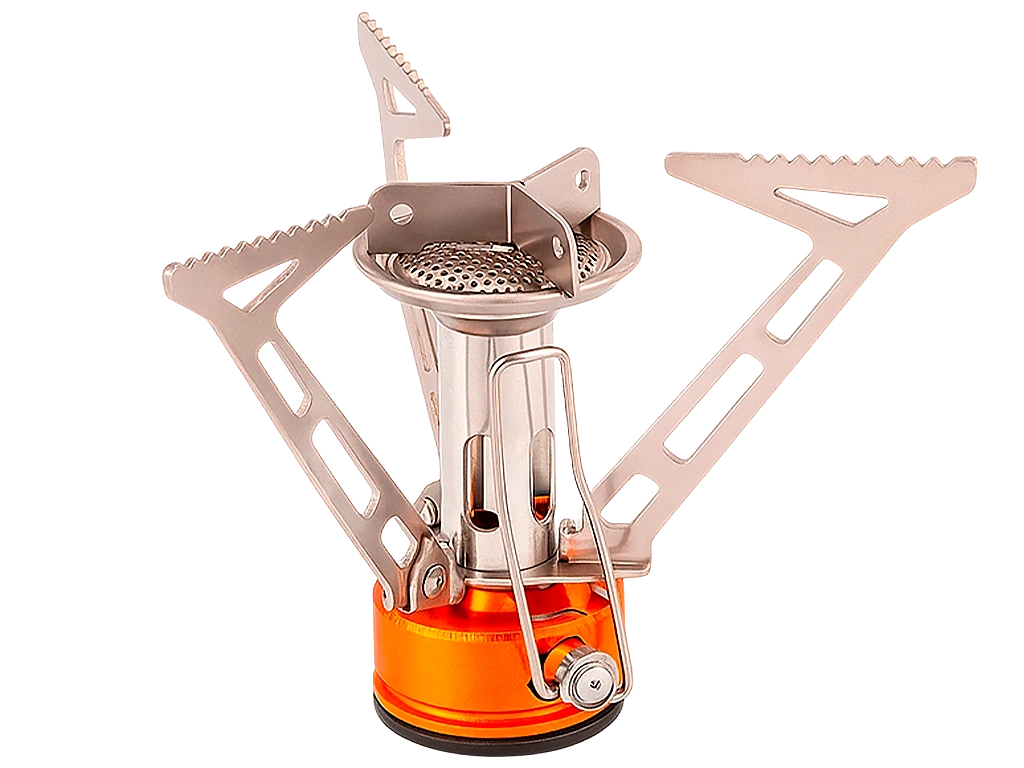

- Gas equipment

- Lanterns

- Bags and suitcases

- Rigging

- Automatic tents

- Tents

- Sleeping

- Korky

- Backpacks

- Shovel

- The knives

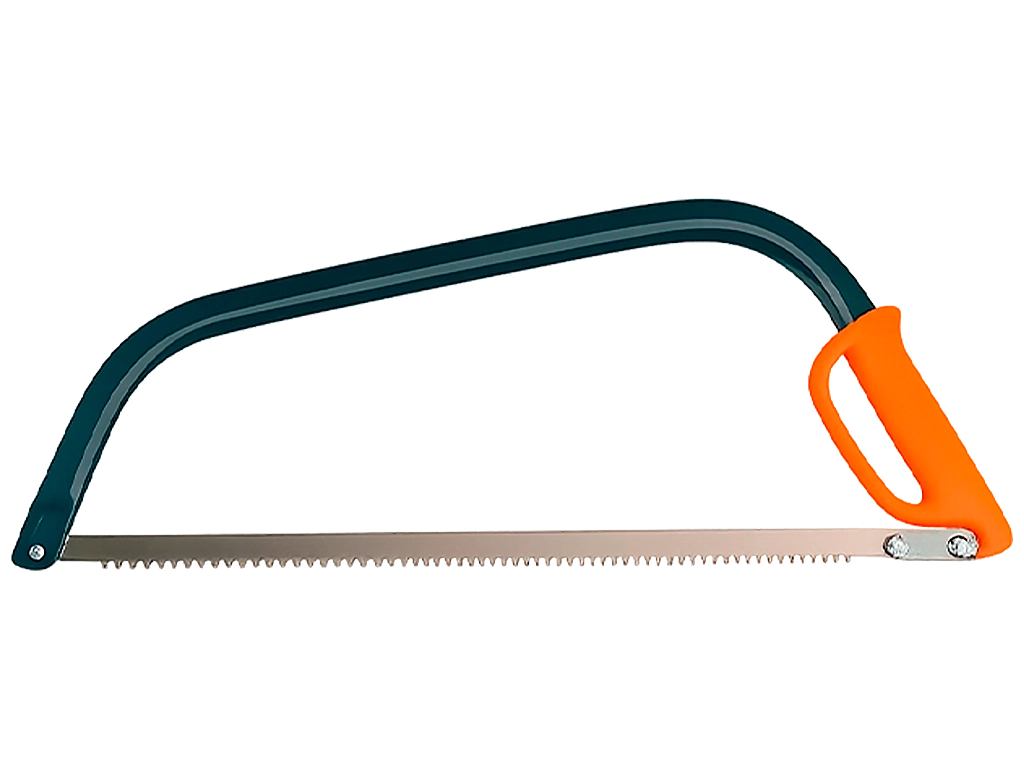

- Hacksaws

- Quick Fist mount

- Axes

- Equipment

- Picnic fuel

- Accessories for tourism

- Clothes and accessories

- Thermos

- Case

-

Canopies

-

Roller Shutters

-

Tonneau Covers

-

Bed Mats & Liners

-

Cargo Organizers & Slides

-

EZ-Down Tailgate Dampers

-

Power bumpers

-

Protection of the bottom

-

Tarcopes

-

The thresholds for the car

-

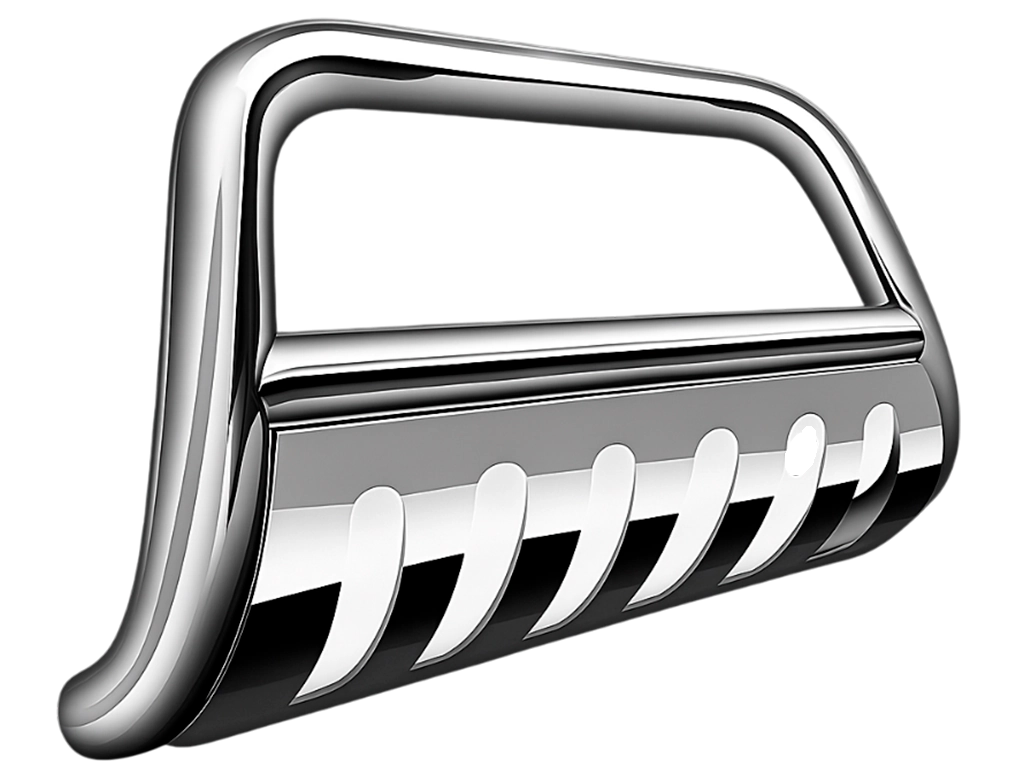

Kangaroo and arcs

-

Expanders and protection of arches

-

Chromium lining

-

Brizhoviks

-

Stylization of the car

-

Deflectors

-

Winches

-

Rigging

-

Dumps

-

Road mixture spreaders

-

Trailer

-

Components and spare parts for trailers

-

Boxes and baskets on the roof

-

The trunk

-

Snorkel

-

Fuel tanks

-

Automatic tents

-

SUV tires

-

Disks for SUVs

-

Spare parts for ATV

-

Shockizer of hood

-

Амортизатори багажника

-

Soft roof, awning, racks

-

Doors and mirror

-

Brake systems

-

Increased clutch

-

Suspension Kits

-

Shock absorbers

-

Shock absorber racks

-

Spars

-

Damper

-

Suspension springs

-

Springs

-

Earrings and fastening springs

-

Springs

-

Springs under springs

-

Silent blocks and more

-

Torsions

-

Differential

-

Wheel couplings (hubs)

-

Wheel spacing

-

Car bearings

-

Panara thrust

-

Side thrust

-

Steering

-

Control levers

-

Transverse stabilizers / mounting parts

-

Drive shafts

-

Generators

-

The engine cooling system

-

Starters

-

Fuel system

-

The system of inlet and release

-

Other suspension spare parts

-

Charging stations

-

Solar panels

-

Electric Vehicles

-

Radios and radio stations

-

Rear -view chambers

-

Ajax

-

Power Bank)

-

Quadcopters

-

Inverters (voltage converters)

-

Voltage stabilizers

-

Car chargers

-

Parkronics

-

Registrars

-

Action cameras

-

Generator

-

Batteries

-

Uninterrupted power sources (UPS)

-

Multimedia systems

-

Jumper cables

-

Turbofans

-

Signals

-

Engine preheaters

-

Autonomous heaters

-

Fans, fan heaters

-

Automobile alarm

- Call me back

- Complaint to the director

- Notify me when available

- Home

- Accessories

- Pneumatic tool

- Tools

- Pneumatic jumper

Pneumatic jumper

pneumatic crackers: varieties, characteristics

pneumatic crackers belong to the category of professional tools. They are used in the assembly/disassembly of different mechanisms. The source of energy is compressed air, which is injected with the compressor. Adaptations differ in low weight, ease of use, compactness and performance, which makes them in demand at machine -building enterprises, in automobile workshops.

Types of pneumatic crack

tools are available with long, short, straight and G-shaped handles. The choice depends on the place of work. Ideally, you should have several devices of different types at hand. For high -quality grip and prevention of sliding handle cracks are covered with a special coating.

devices are also divided into:

- unstressed - influence on mounting is carried out by rotational movements that are optimal for working with small connections;

- Driving - suggest shared use of rotational motion and shock pulses suitable for rusty compounds.

pneumatic cracks can have different planting square. 1/4 inches are intended for small parts. 3/8 inches are relevant to work with M10 mounts. 1/2 -inch -square crackers are most widespread, suitable for suspension, transmission and other vehicles.

tools can contain different number of teeth in the range of 24-72. The smaller their number, the more the load is able to withstand the mechanism. A device with a lot of teeth is more convenient when work is done in a hard -reaching place.

cracks are completed with 2 types of switches - annular and flag. In the last step of turn more so they are better for places with limited space.

cracks are made mainly of steel with the addition of chromium and vanadium. Such material has increased strength, is not afraid of environmental effects.

What is taken into account when choosing a pneumatic crack?

one of the key characteristics that should be addressed except the above:

- Rotation frequency - determines the speed of work;

- torque-indicates the capacity of the device for one hundred rationally to buy tools with 70-100 nm;

- Air consumption - affects compatibility with the compressor.

You can order pneumatic chips inexpensively and with delivery in Ukraine in the online store "Vnedorognik". The assortment has separate tools and kits with shock heads from the best manufacturers, such as Force and Sumake . To make a purchase, add the appropriate model to the Basket and specify the contact data, the desired method of delivery and payment. The departure is made within 1-2 days after the purchase is confirmed.