Contents:

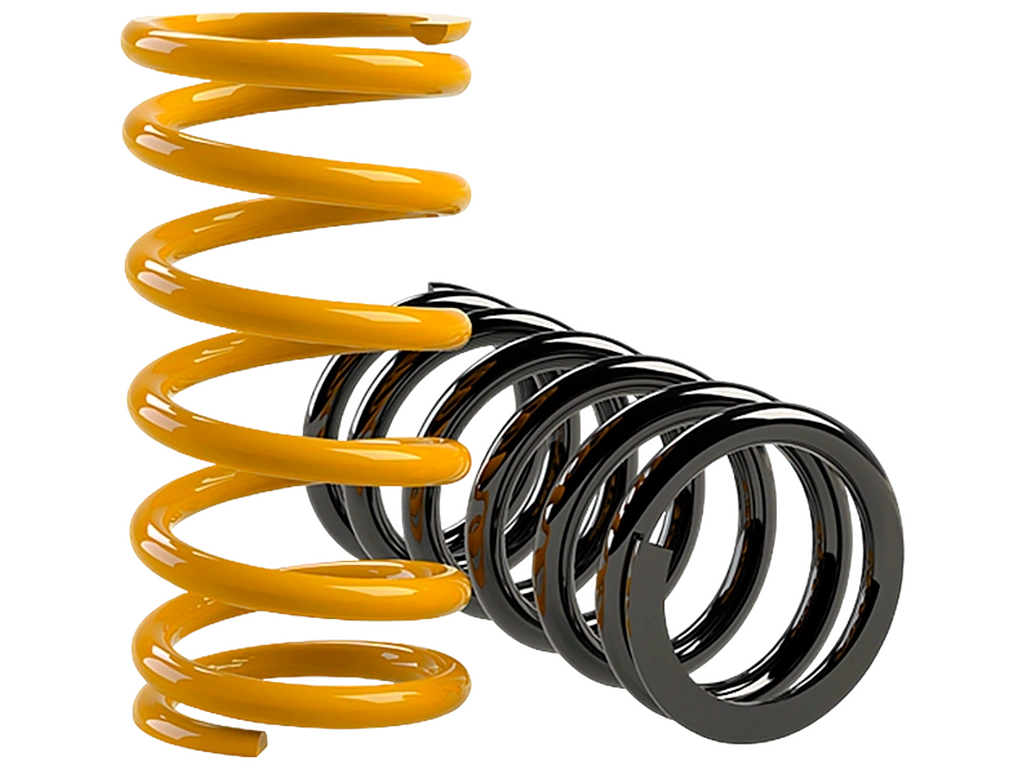

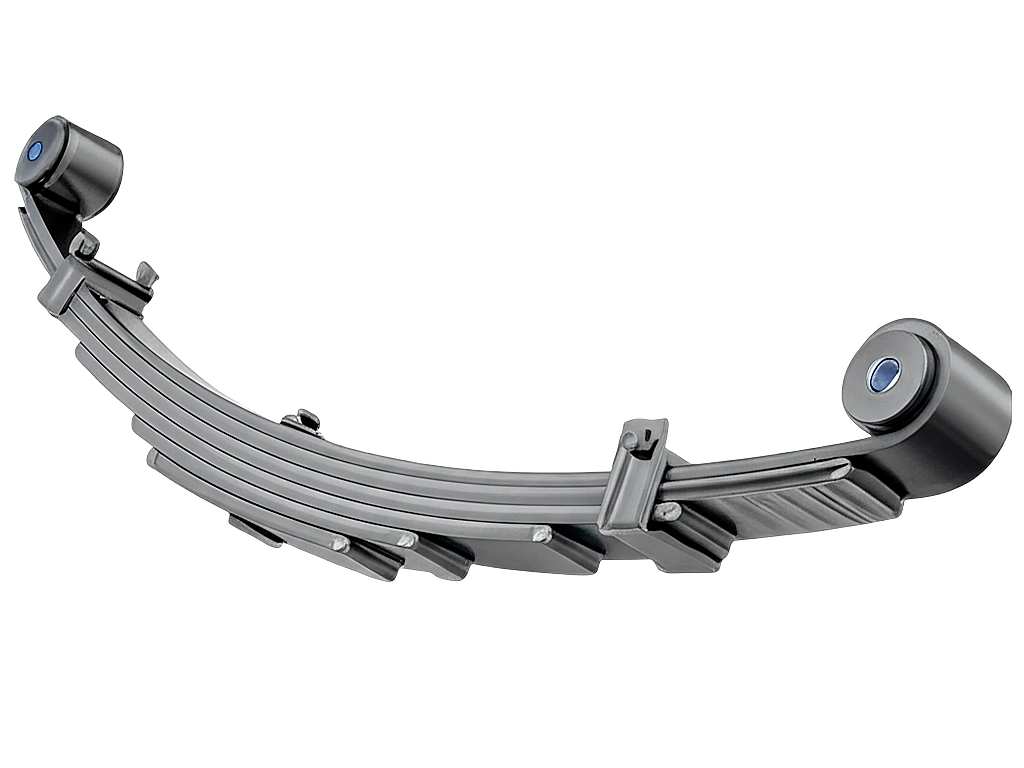

your car springs are crucial for the safe drive and comfort of travel. They maintain a constant height and provide elasticity to absorb the inequalities of the road . The spring not only holds the car and supports the clearance on the road. It also determines how the machine will respond to obstacles. Spring manufacturers design them so that the body does not sink too hard during the transportation of goods or passengers. And if you want to carry more cargo in the car, you can buy reinforced springs , which are made for almost all machines.

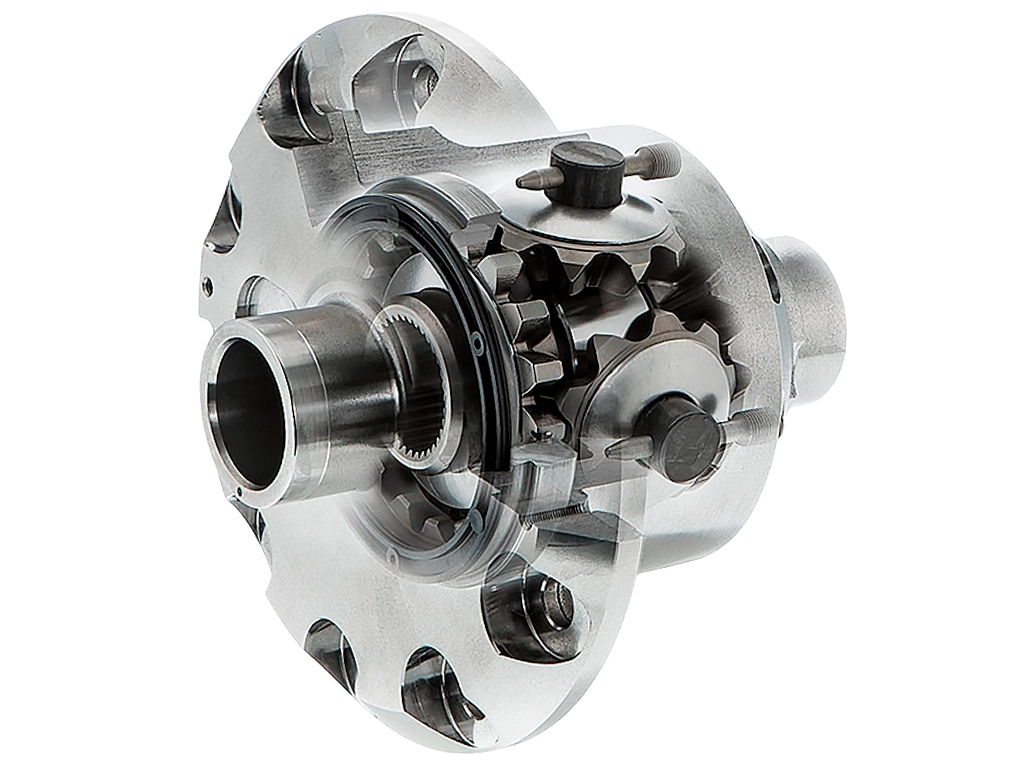

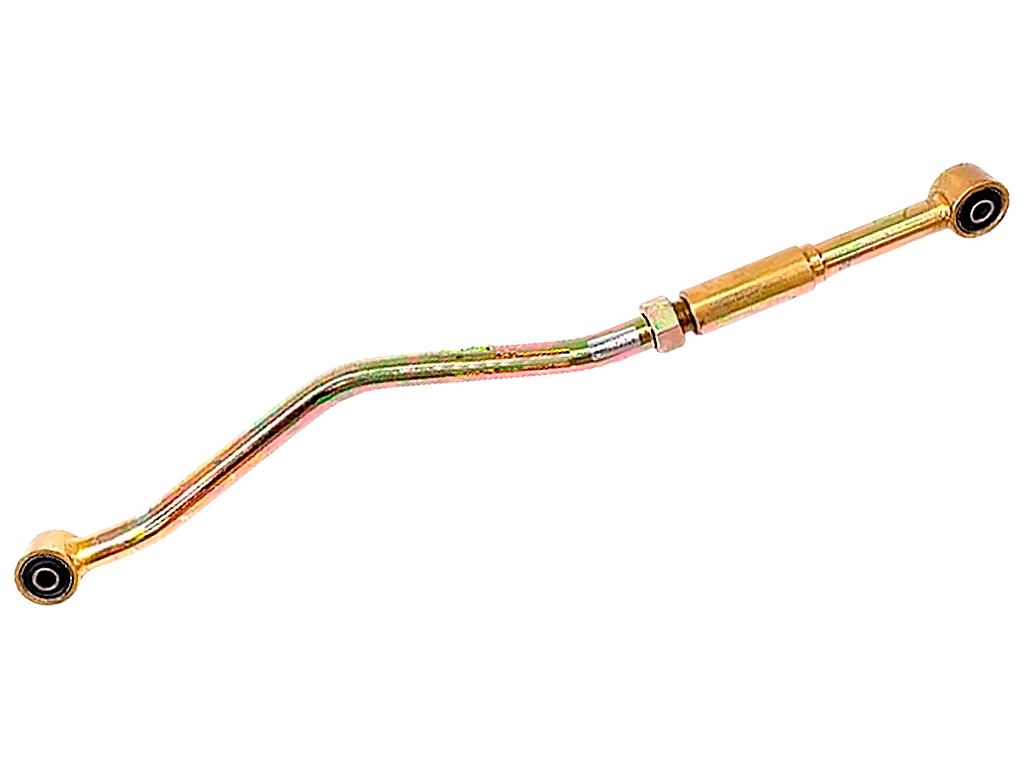

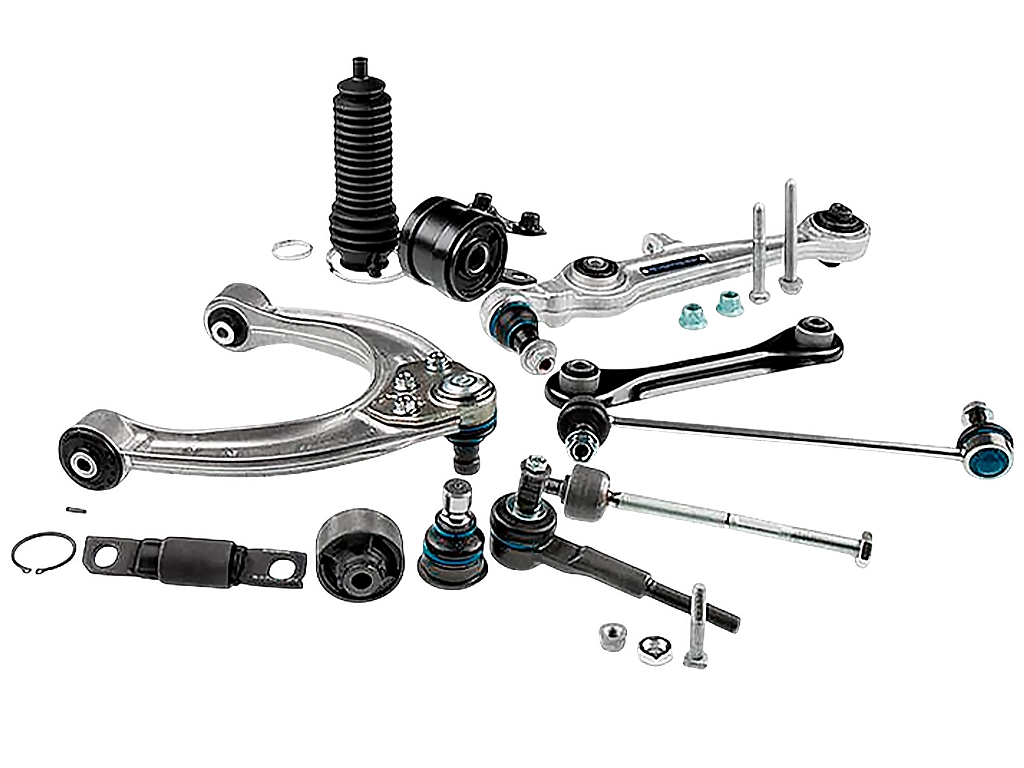

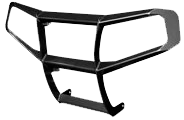

all Suspension elements , such as levers, thrust, stabilizers, ball supports and sailblocks, exist only to do a lot> to keep the wheel always in contact with the road.

What is the need for springs?

screw or spiral springs are made of hardened steel in the form of a spiral.Most modern cars have these suspension elements on the front axle, and quite a few pickups and SUVs on all four wheels. If on your car shock absorbers are attached separately.

What is the degree of compression of the spring?

the main parameter is the rigidity . The higher the rigidity of the spring, the more strength you need to squeeze it. This characteristic is influenced by other parameters, including the external diameter and height, shape, step of the coil, the diameter of the wire, the number of turns and the characteristics of the material. The stiffness also depends on the diameter of the rods: the thicker rods make the spring stiffer.

the length of the spring is its unprocessed length, and the higher it is, the higher the rigidity.

In the same spring step of turns (the distance between turns) can be constant or variable. Short coils absorb the small irregularities of the road well, while long turns maintain the rigidity and controllability of the suspension.

Popular forms of springs:

- barrel -shaped : have a convex outer and concave inner surface to increase capacity. Since the rigidity changes unevenly, such springs are well adapted to load.

- Sandbathing springs : a unique shape with a narrow central part and wider ends ensures increased flexibility and resistance to inflection in high load conditions.

- conical : have turns with a variable step that have no contact with each other and are characterized by a greater course, more progressive compression resistance and high load capacity.

- usually (cylindrical) : These are cylindrical springs with the same diameter and step. The turns of the same diameter face each other during complete compression and make linear resistance.

The benefits of spiral springs:

Use screw springs pendants that provide the highest versatility in different conditions . They make it possible to achieve comfortable driving for unloaded cars and become harder as weight gain, increasing stability without bouncing and preventing a significant reduction in clearance.

? For SUVs, the spring suspension increases the suspension in the rough terrain and get contact with the surface even in the most difficult relief.The disadvantages of screw springs:

If compared to the springs, the springs do not tolerate heavy loads. The weight of the machine is concentrated on a smaller surface area, while leaf springs distribute the load evenly.

To save weight, some manufacturers make springs thinner and lighter, but this relief is more likely to subside and destroy under pressure, especially if corrosion occurs. Some manufacturers of springs, such as ironman or When to change springs?

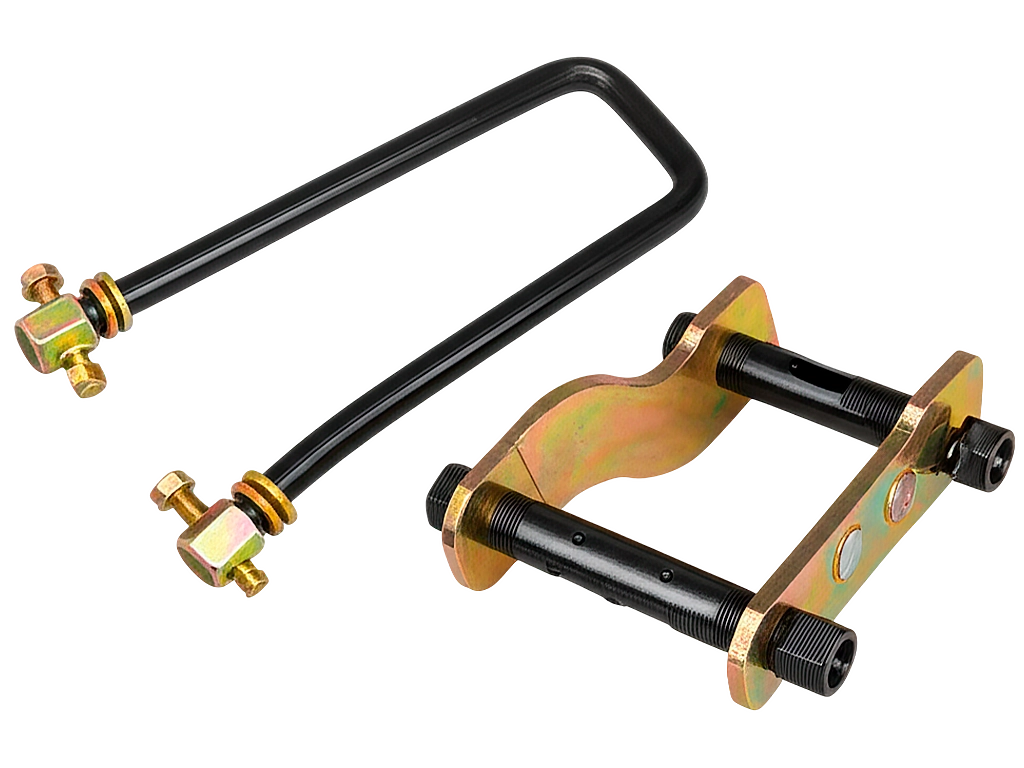

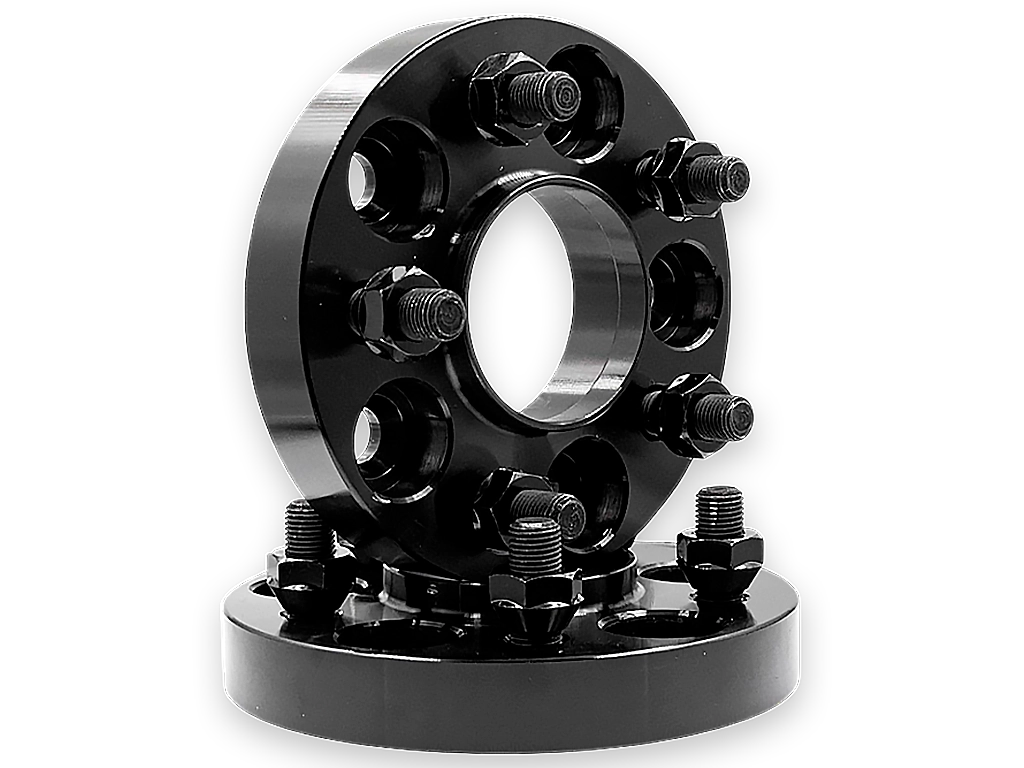

Over time, the twisted springs wear out and begin to settle , causing the car clearance to decrease. The spring can also be broken if the suspension height is noticeably different from the left and right side of the car. These problems become more obvious when you add even a small weight, such as one or two passengers in the back seat. Broken springs can also produce a noticeable roar and damage other parts. Their should be changed immediately not to "get" for a more expensive repair. springs are often used in vehicles with a multi-weight suspension, so if the suspension height is broken, it can may affect the collapse of wheels and tire wear . To check whether you have a suspension height, you can find specifications in the operating instructions or on the Internet and compare them with your own measurements. If you just need to replace the work output, and in the suspension everything suits you, it is better to choose the original spring (you should change the springs in pairs in order not to expose a new spring to the worn out on the other side of the axis). If you want to improve the suspension characteristics, we have reinforced springs from the best world manufacturers, intended for this. We also offer kits for suspension lift, spacer and sets for leveling SUVs and pickups (which lift the front of the car more than the back to align the car relative to the surface).

Which springs to choose?