Have you ever wanted to know more about these strange rotor engines of Vankel? Here is our full guidance on one ever created the most controversial engines.

Despite the fact that Vankel's rotary engine has been over 60 years old, its concept is still often misunderstood. If you spent some time in the automotive internet space, you know that rotary engines have a reputation unreliable. However, as we now show, this reputation is not quite fair. Although, do not understand us wrong, there are other drawbacks that are worth knowing. But before you go to this, let's bring you into the course of the case and tell you what a Vankel rotor engine is ...

Contents:

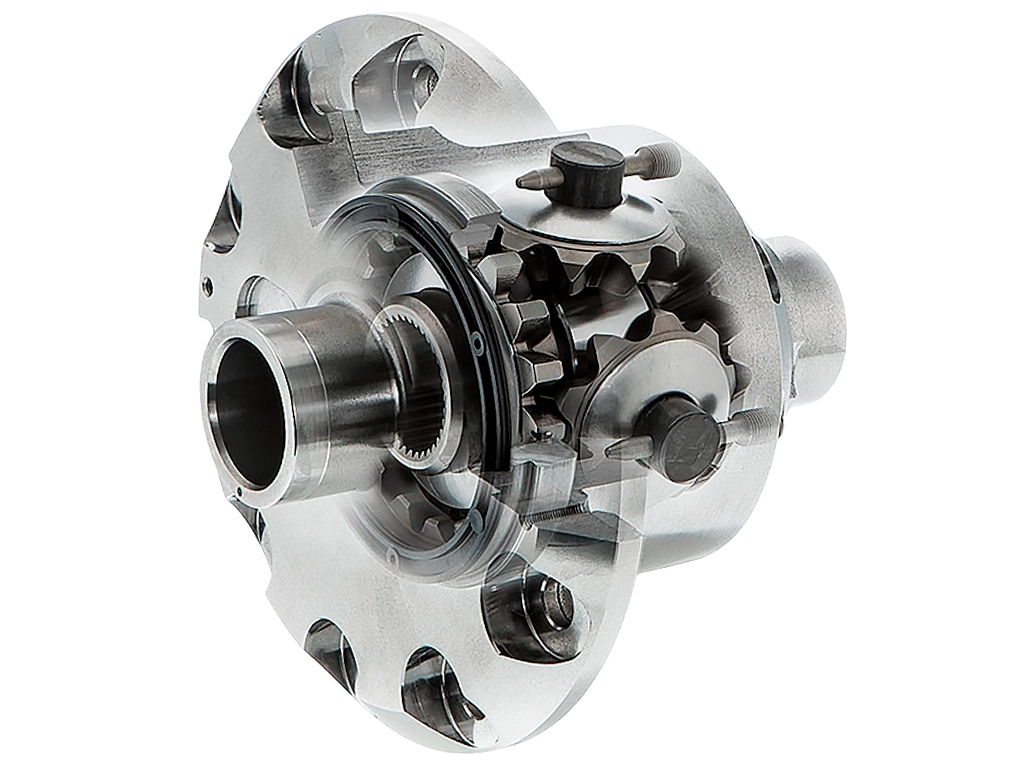

input As the name implies, curved triangular rotors are used in Vankel's rotary engines. They are located vertically in the oval body and rotate around the output shaft.When the rotor rotates, it creates air pockets, with each other and the walls of the housing in different places along the inner perimeter of the housing. Vacuum in these pockets draws air and fuel mixture into the body. Consider this equivalent to the inlet of the piston engine. burning Then the second "top" of the triangular rotor closes the path of the air-fuel mixture when it passes by the inlet. As the rotor continues to rotate, the space between it and the wall of the body decreases. As a result, the air-fuel mixture is pressed against the wall of the opposite side of the body. There is a certain part of the wall where the compression will be maximum during the rotor rotation cycle, and there you will find a couple of spark plugs. They set fire to a strongly compressed mixture of air and fuel, and voila, combustion occurs. The mini-mini mini-mini sets drives the rotor, continuing its cycle. As the rotor continues to rotate around the housing, its first peak will soon meet with the exhaust hole. When the peak passes by the hole, it opens the duct to exit the exhaust gases. And here he is, the full cycle of combustion of the rotary engine. In fact, the designers have increased the size of the rotor and its body in such a way that as long as the exhaust process is taking place, the third vertex of the rotor will already be near the inlet opening, drawing another portion of the air-fuel mixture. And so, the cycle continues, bringing the rotor, which, in turn, drives the "eccentric output shaft" (essentially, the crankshaft), which transmits the engine energy by the transmission to the wheels. How does Vankel rotor engine work?

If you ask enthusiasts with which cars they have the most associated rotary engines, then they are likely to answer that with Mazda RX Sports Cars.However, the Japanese brand was not the first to apply rotary technology in its serial cars. This honor was now awarded the non -existent German NSU brand.

German origin

It would not be surprising if the history of the rotary engine was over. However, despite the NSU, Mazda decided to take this technology and invest in Vankel and his ideas.

Mazda Association with Vankel Rotary Motors

the rest of this story, I'm sure will be familiar to many of you. It is an enterprise that ultimately led to the creation of a Mazda RX sports vehicle line, the most famous RX-7 and RX-8 models. RX-7, in particular, is a real car icon. On the route, the first generation won the grueling race "24 hours of Le-Man" (a rather large feat for a car with a "unreliable" reputation), and later models became icons of modification and tuning.

These RX-7 and RX-8 use a two-year structure known as the 13b engine. Two rotors are located 180 degrees from each other, which means they complement each other during the combustion cycle. In other words, as the peak of one rotor enters and passes the combustion stage, the second rotor is a little behind, ready to take the load when the first rotor goes to the exhaust.

In rare cases, you can also buy 3- and 4-rotor Vankel engines for extra power. More rotors mean less time between the combustion stages of each rotor, which provides a smooth and powerful energy supply. The four-year engines in the past were usually installed on racing cars, in particular, on the Mazda 787b , which won the absolute victory in Le-Man. However, nowadays we begin to see extreme tuner assemblies with these almost mythical four -year -old 20B engines.

There are many reasons except for the simple factor of novelty, why some people love these rotary engines. To begin with, one rotor effectively performs the work of three pistons: inlet, combustion and exhaust occur almost simultaneously. In practice, this means more power of a relatively small and light engine.

Another distinctive feature of Vankel's rotary engines is that their rotors move in only one direction. Thus, compared to fragmentary reciprocating motions of piston engines, healthy rotary cars will have a much smoother launch and transmission of power during traffic. Moreover, the absence of reciprocating masses means that rotary engines can develop very high revolutions without much problems.

>Vankel's engine benefits:

compact size and low weight

Low vibration and smooth work

High performance for your size

a small number of moving parts in a simple design

Of course we are not going to pretend that rotary engines are perfect. After all, there is a reason why they are so rare.

Mechanical disadvantages

In the first days of NSU existence, when RO80 began to "die like flies", Vankel realized that vacuum chambers that were created during each part of the combustion cycle could lose compression due to poor rotor compaction. Adding apes seals, of course, helped to solve this problem, but Vankel had to look for a way out of the heating problem.

If the processes of inlet, combustion and exhaust occur in one housing, it turns out that parts of the rotor and wall wall reach very different temperatures. And, as you will tell you physics lessons in high school, metals can slightly change the shape at different temperatures. Therefore, in the scenario, which is based on the perfect sealing between the rotor and the walls of the body, it can be problematic. To soften this problem, Wankel introduced "scars" cooling around the perimeter of the walls of the body, but ultimately this problem cannot be solved perfectly. Physics simply will not allow you to do it.

Moreover, in the process of combustion cycle, there is a huge amount of friction when the rotor passes past the walls of the body. Therefore, rotary engines drink motor grease like alcoholics on Oktoberfest, which means that they require much more careful maintenance than usual

compared to conventional engines, lower fuel efficiency

incomplete combustion leads to increased emissions into the atmosphere

frequent replacement of rotor increases the cost of maintenance

high operating temperature and limited torque

Economy and ecology

Conclusion

Conclusion

Therefore, Vankel's rotary engine has many advantages in terms of performance. Higher specific power, smooth flow supply and relative weightlessness - all these characteristics will appeal to such motorists as we are with you.

But the Internet is not at all right.These engines really have "Achilles heel", and in order to last as long as possible, you will have to be treated more seriously than any other car. However, for some people it is the price that you should pay for the fun you will get when you sit behind the wheel.

Besides, although RX-8 ceased to exist in 2012, it seems that the rotary power units still have a future, despite their ten-year break. Emissions laws block the creation of any future full-fledged rotary models, but Mazda has just announced its intentions to use rotary technology as a hybrid expansion of the EV range. So, who knows, perhaps in our electrified future, there will be a place for a revived RX sports car ...

>>

Of course we are not going to pretend that rotary engines are perfect. After all, there is a reason why they are so rare.

Mechanical disadvantages

In the first days of NSU existence, when RO80 began to "die like flies", Vankel realized that vacuum chambers that were created during each part of the combustion cycle could lose compression due to poor rotor compaction. Adding apes seals, of course, helped to solve this problem, but Vankel had to look for a way out of the heating problem.

If the processes of inlet, combustion and exhaust occur in one housing, it turns out that parts of the rotor and wall wall reach very different temperatures. And, as you will tell you physics lessons in high school, metals can slightly change the shape at different temperatures. Therefore, in the scenario, which is based on the perfect sealing between the rotor and the walls of the body, it can be problematic. To soften this problem, Wankel introduced "scars" cooling around the perimeter of the walls of the body, but ultimately this problem cannot be solved perfectly. Physics simply will not allow you to do it.

Moreover, in the process of combustion cycle, there is a huge amount of friction when the rotor passes past the walls of the body. Therefore, rotary engines drink motor grease like alcoholics on Oktoberfest, which means that they require much more careful maintenance than usual

Economy and ecology Therefore, Vankel's rotary engine has many advantages in terms of performance. Higher specific power, smooth flow supply and relative weightlessness - all these characteristics will appeal to such motorists as we are with you. But the Internet is not at all right.These engines really have "Achilles heel", and in order to last as long as possible, you will have to be treated more seriously than any other car. However, for some people it is the price that you should pay for the fun you will get when you sit behind the wheel. Besides, although RX-8 ceased to exist in 2012, it seems that the rotary power units still have a future, despite their ten-year break. Emissions laws block the creation of any future full-fledged rotary models, but Mazda has just announced its intentions to use rotary technology as a hybrid expansion of the EV range. So, who knows, perhaps in our electrified future, there will be a place for a revived RX sports car ...

compared to conventional engines, lower fuel efficiency

incomplete combustion leads to increased emissions into the atmosphere

frequent replacement of rotor increases the cost of maintenance

high operating temperature and limited torque

Conclusion