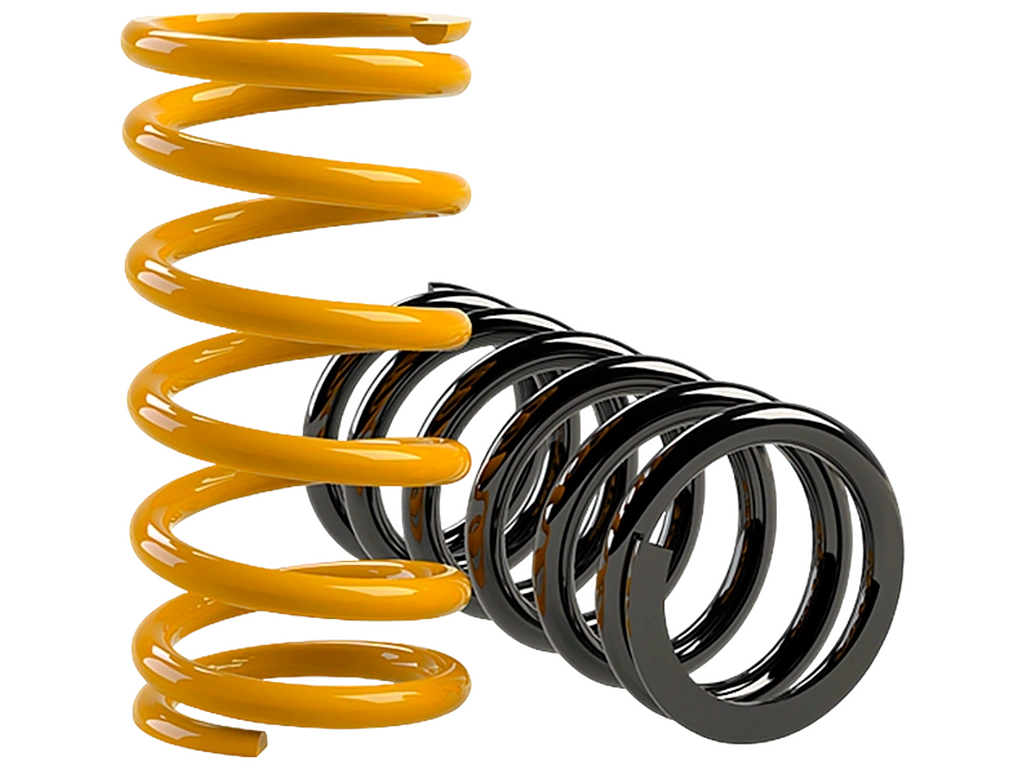

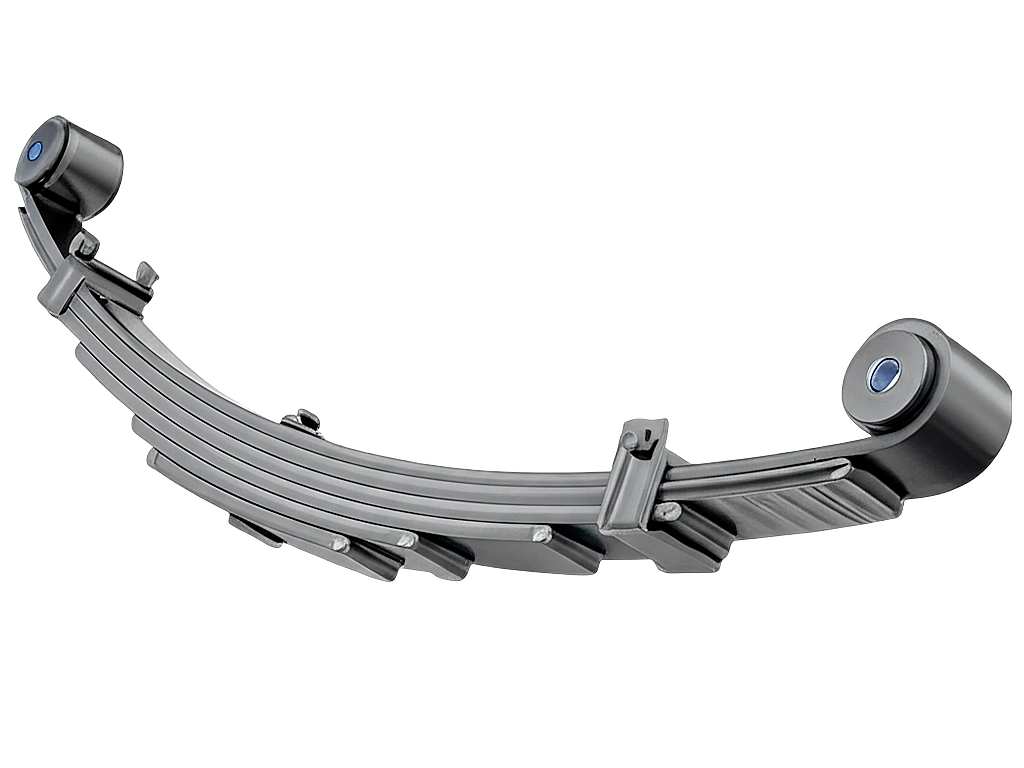

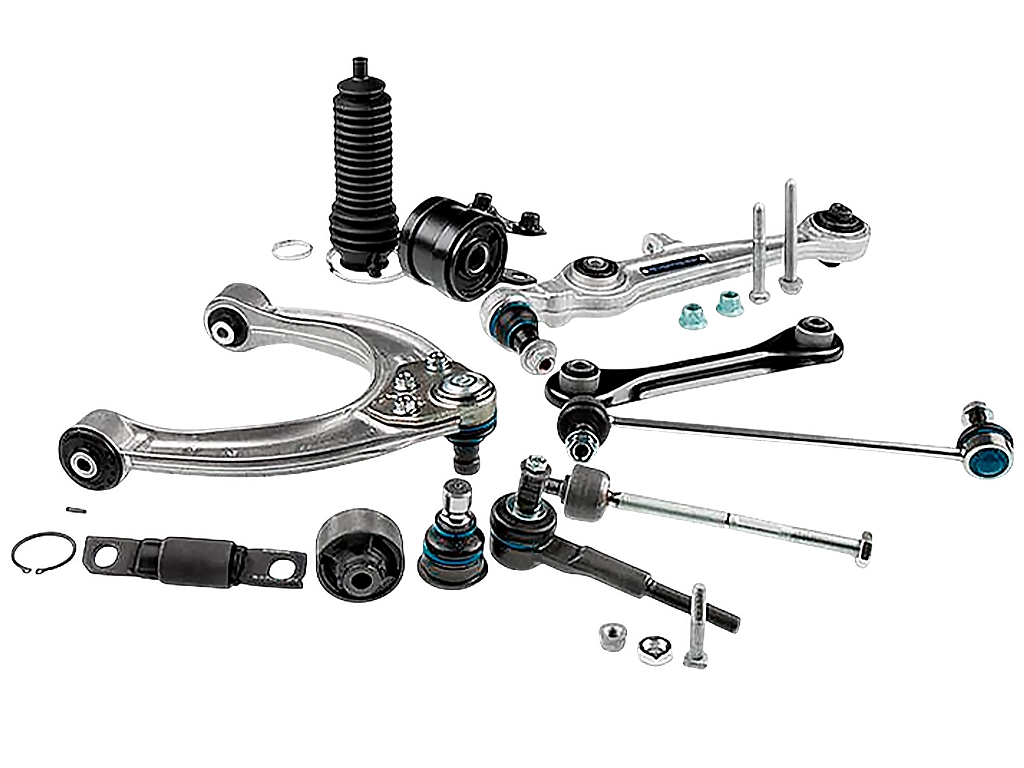

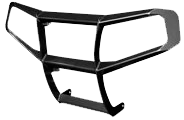

springs have been used for a long time, long before the invention of cars. They are made of steel and similar to arcs, maintaining the weight of the car and holding the axis in place.

springs have been used for a long time, long before the invention of cars. They are made of steel and similar to arcs, maintaining the weight of the car and holding the axis in place.

Automoffers who seek to improve the running qualities of light cars have developed monolic springs. Since these springs are the thickest in the center and the thinnest at the ends, a variable rigidity (like springs) is created, and they support the weight of the car and hold the axis in place. As a result, the use of such springs improves the quality of the trip on small cars and provides a soft ride, helping to drive a car on steep turns.

There are currently two most popular types of springs: single -leafed and multi -leaved . The former are used for small cars, and multi -leafed for large vehicles. But what is the difference between them and what other springs can be?

in this article you will learn:

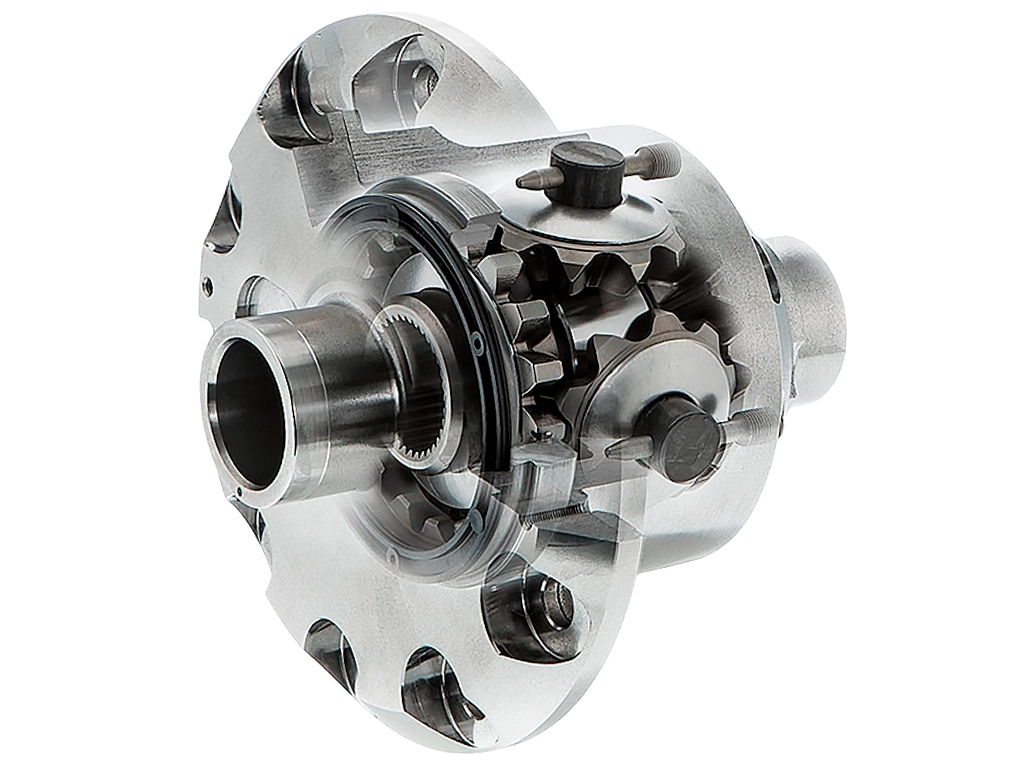

How is the spring suspension arranged?

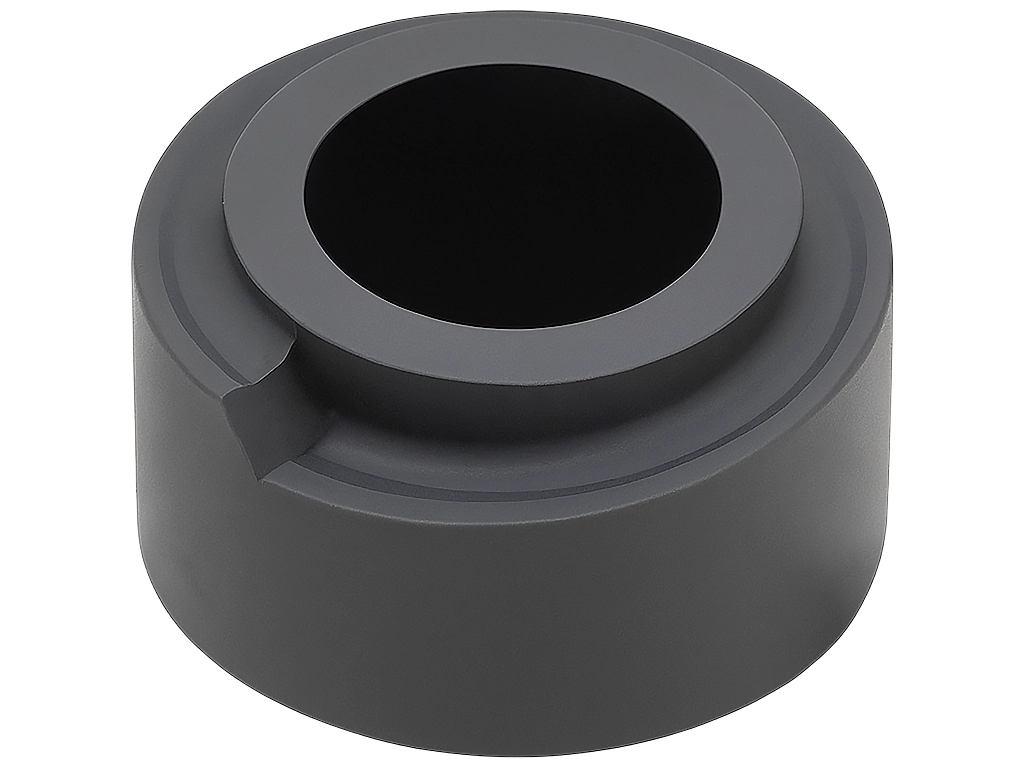

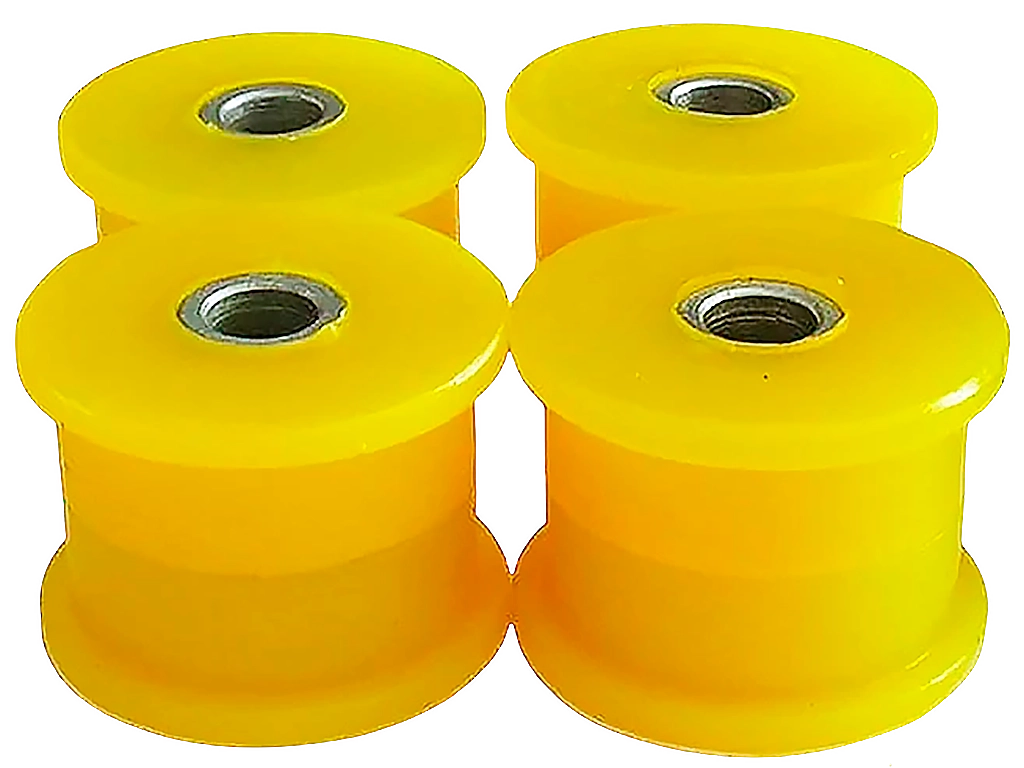

Central steel sheets are responsible for mounting the suspension to the bridge of the car, and the endings of the sheets are connected with the frame of the car with the help of hinges or earrings.

Some sinking systems have only one metal sheet, not several, such systems were used in the middle of the last century in the United States. These systems were installed on the car of the brand Ford , and only in a few years this system has become popular with European car manufacturers.

? auto; />when encountered with obstacle, the spring sheets are slightly bent , extinguishing all the fluctuations that have arisen. If there are several sheets, then the heavy load falls on the lower restor, so it is made shorter, achieving the smallest bend. The upper springs, on the contrary, make longer to achieve more flexibility and extinguish the fluctuations remaining after the lower sheets.

Today, springs are used in pickups, SUVs and large trucks. They are installed in front, back, along frame beams or transversely on different types of suspension .

The disadvantages of spring suspension:

- When the springs are attached directly to the rear axle, the torque that occurs during sharp acceleration or braking can cause the axis to scroll. This leads to vibration and significant squatting of the back of the car.Such fastening also requires rigid springs, which reduces the level of riding comfort, which could provide softer springs .

- This design provides very low adjustability and is not suitable for suspension tuning, because adjustment is possible only by changing the number of sheets in the package of springs or changing the composition of the material in order to change the characteristics of strength and flexibility. For example, Chevrolet Corvette T56 (5 generations) uses plastic springs reinforced with fiber.

What are the types of springs?

- Multiple

- Monolist

- semi -Eliptical

- Quarterly

- three -four elliptical

- full -elliptical

- Cross

by the number of letters:

- multi -leaved spring

The most common type is a multi -leafed spril, which consists of more than one metal plate or sheet. These plates are stacked on top of each other, and the longest part is on top. Through the thickest part, a central bolt is inserted, which holds the plates together. Standard components have three to five shutters, but can be found with more.

multiple leaves increases the rigidity of the spring . Additional support leads to an increase in load capacity, so such springs are suitable for high -load vehicles. But be careful when using a spril with too many leaves, as it can lead to excessive stiffness and cause uncomfortable riding.

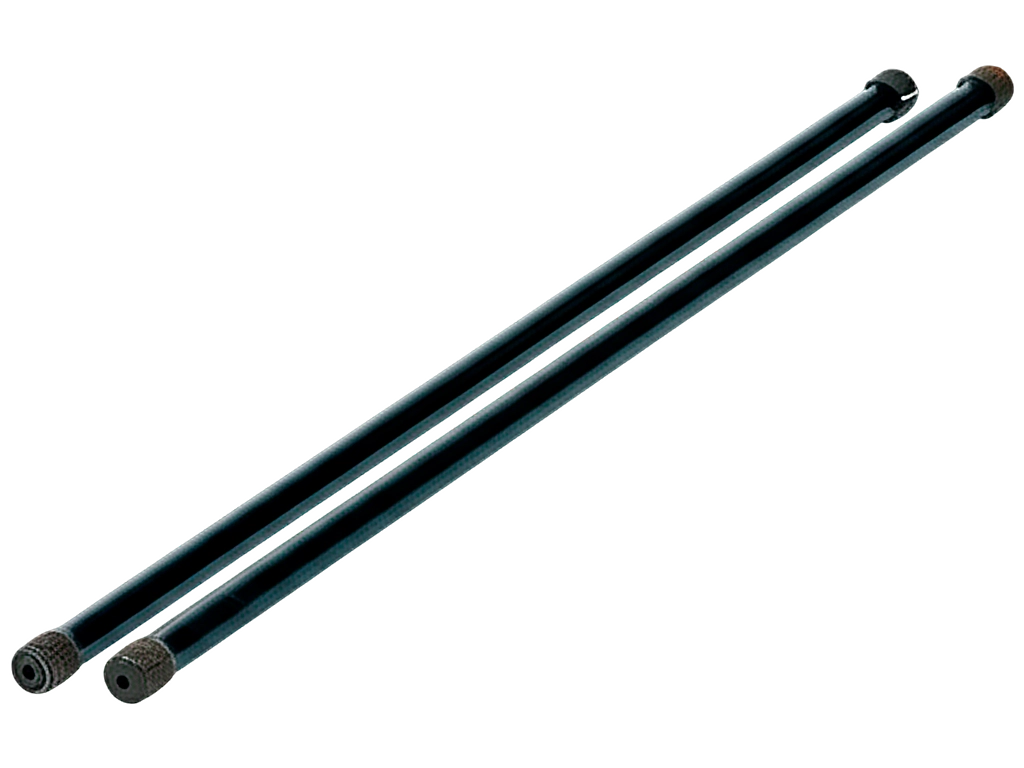

- Monoleys of the spring

Another type is a monolist spring made of one sheet of metal. They have a thick central part and narrow to the edges - to support, as well as multi -leaved springs. They are mostly used on light cars.

in the form of leaf springs:

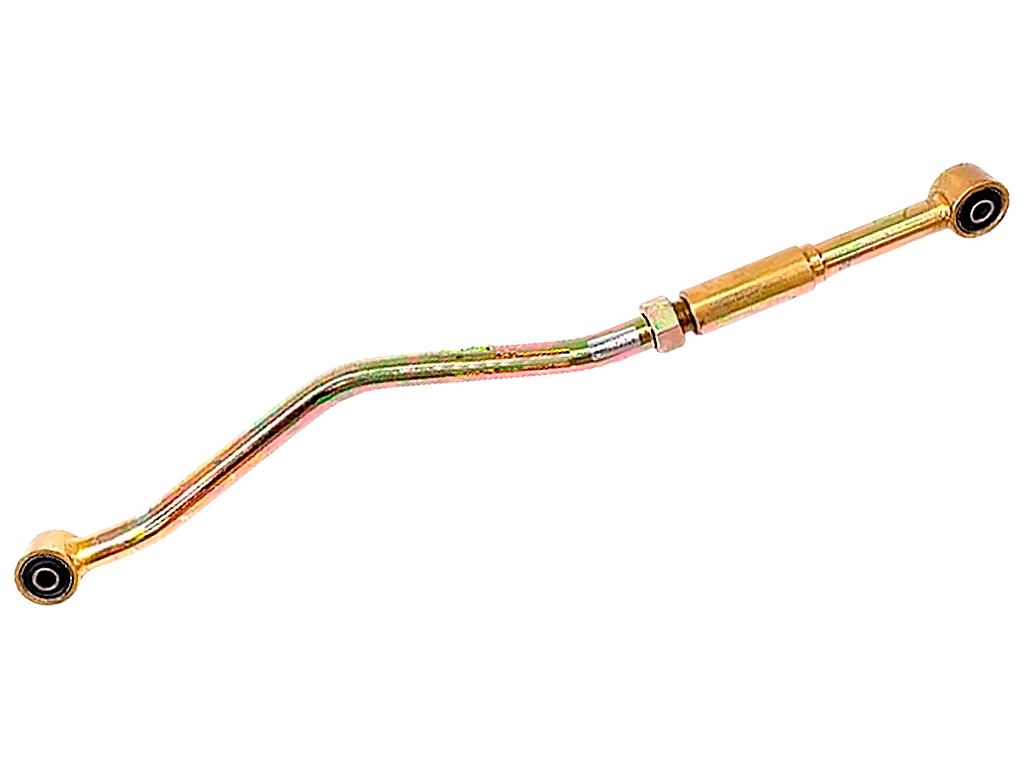

- semi -Eliptical springs

This is the most common type of listed here. It consists of several sheets of the same width of different lengths, including the upper and longest sheet called the "main sheet". They are attached to the frame of the car and brackets. The semi -Eliptical springs are installed on the front and rear axles of many vehicles, mainly on the back axis of cars. They are available at a price, serve for a long time and do not require frequent repairs.

- Quarterlyptic spring

This type is similar in design to a semi -Eliptical compatible, but they are used mainly on old cars. A distinctive feature of this component of the suspension is that it is only half of the semi -Eliptical springs. One end is attached to the side of the frame with a bolt, and the other end connects to the front axle. This type of spring is also called console.

- three -four elliptical spring

If you combine a semi -Eliptical companion and a quarter -elliptical, it will turn out a three -foot elliptical spring. The quarter elliptical part is located on top of the axis and fastened to the frame of the car. The semi -Eliptical spring on one side is connected to the frame through the bracket and the other end is attached to the quarter -elliptical springs.

Adding an additional half of this suspension component provides additional support. The three -nurtured elliptical spring is popular in old cars.

- full -elliptical spring

is a combination of two semi -Eliptic springs that connect each other, creating a shape similar to an oval. They are attached to the car frame and to the axis. Because during compression, both springs are bent equally, the brackets are not used.

full -elliptical springs are mainly used in old cars. Nowadays, they are rare because they do not ensure proper alignment of the axis.

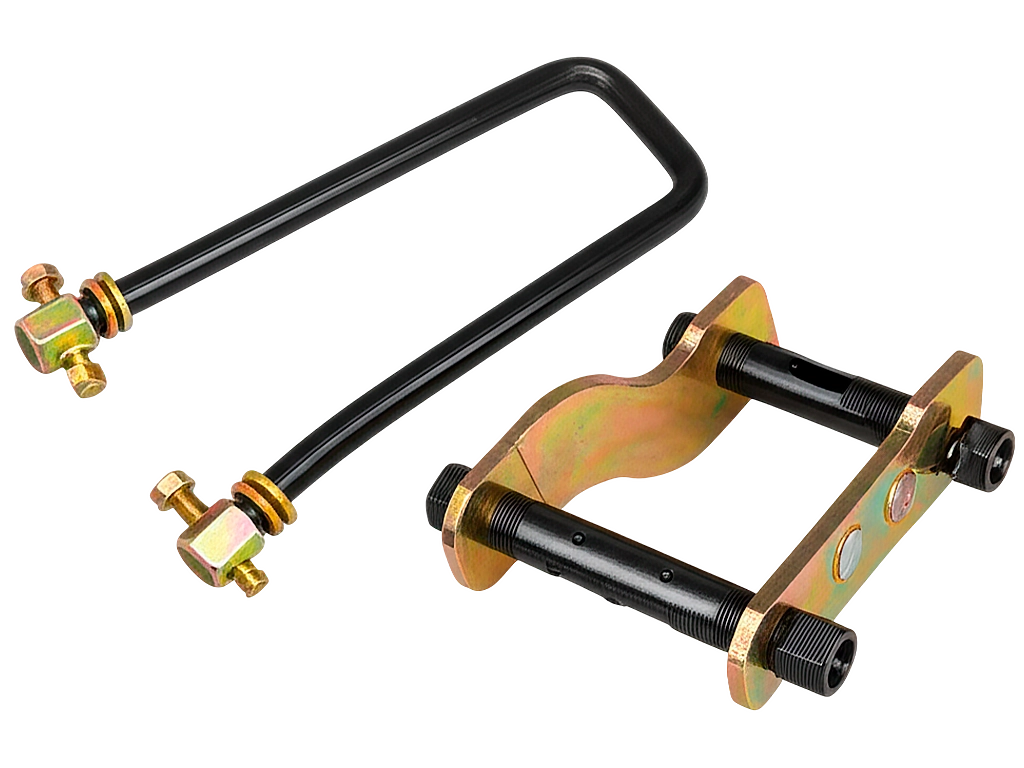

- Crossbar

This type of springs is very similar to a semi -Eliptical spat. The only difference is that it is inverted, so the longest leaf is below. It is attached to each wheel, not above them. The middle or thickest part is attached through the U-shaped bolt. They are also mainly used in old cars, often in independent pendants.

How to determine the wear of the spring?

when worn, the springs lose their elasticity and begin to settle . As a result, the height of the car decreases. If you have a suspicion that the spring is worn, it is recommended to measure the height yourself and compare it with the specifications of the manufacturer. Reduced height and loss of border of springs can lead to complications such as the car -lock on the irregularities, which is harmful to the components of the suspension and the entire car as a whole.

In addition to the above, springs can eventually get cracks and corrosion . When rubber sleeves in the ears of the springs and brackets dry, the ride can become more rigid. You can choose fasteners for springs at this link .

How to serve springs?

but be careful not to harm yourself, in particular, fingers.

but be careful not to harm yourself, in particular, fingers.