Checking the performance

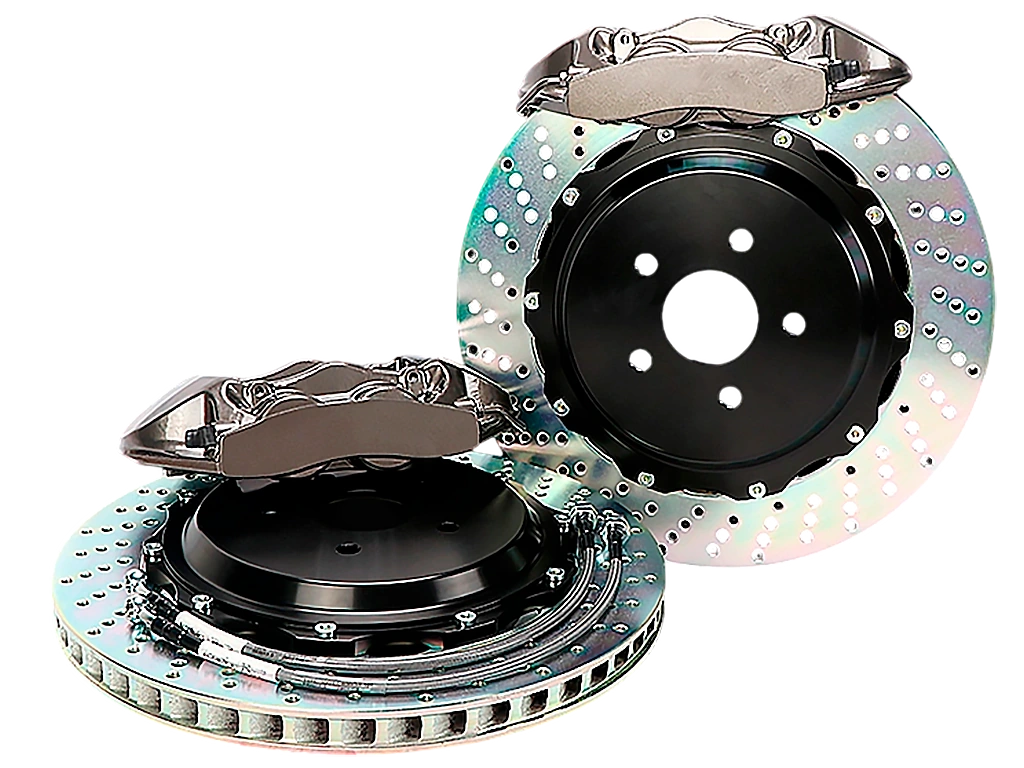

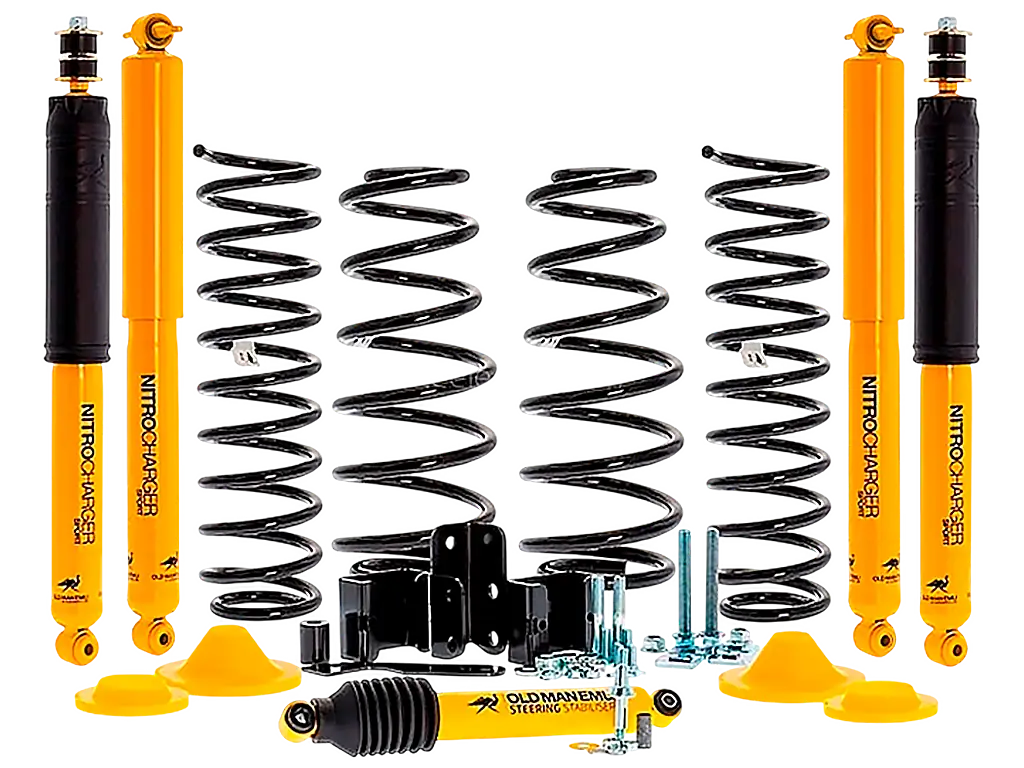

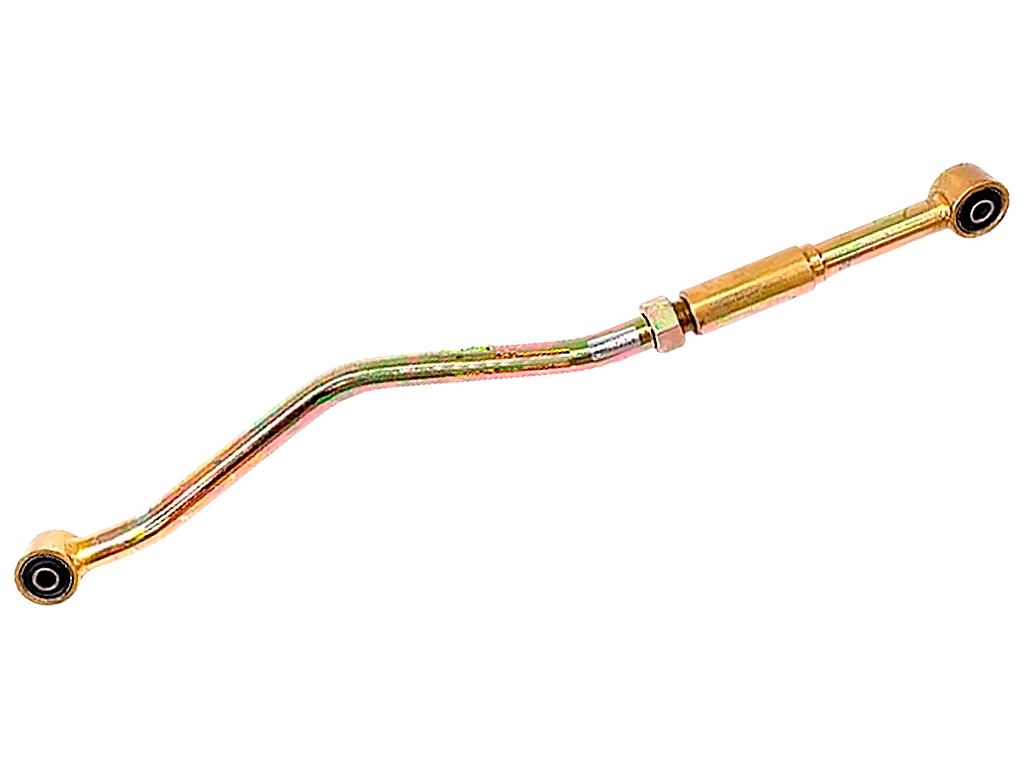

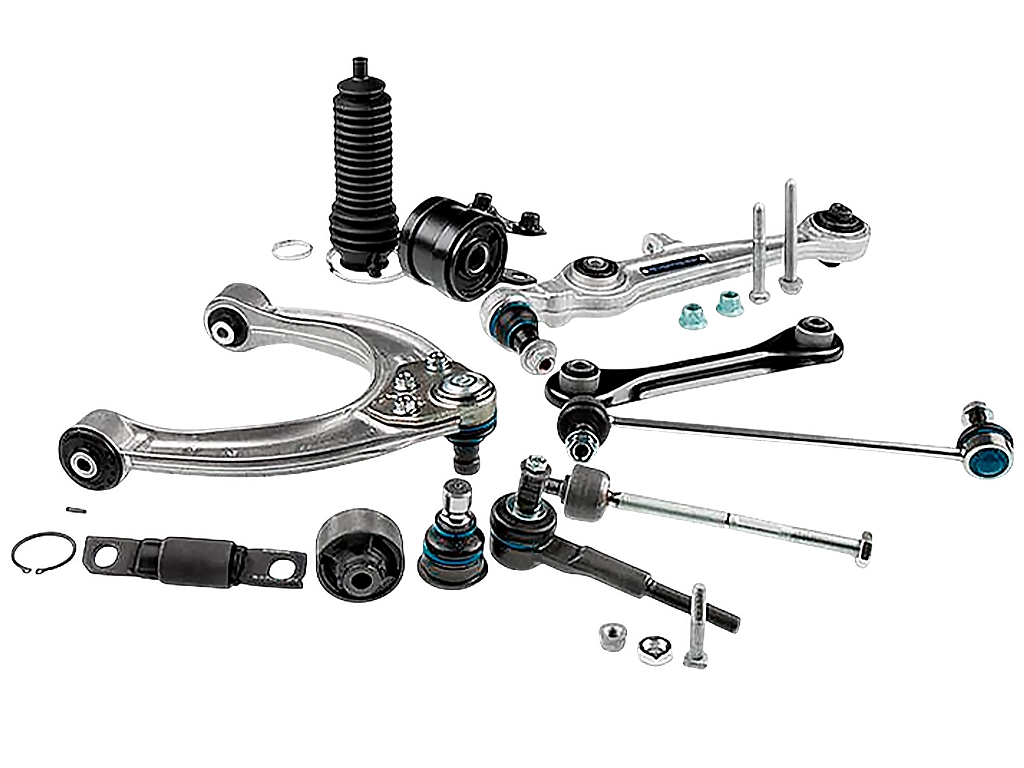

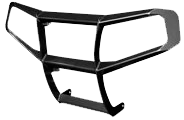

shock absorber racks perform a number of important functions in the car design. With their help, the body and wheels are connected, the correct position of the latter is ensured. The racks are also responsible for the comfort of movement, clutch with the road. Therefore, the operation of worn parts is extremely undesirable and even dangerous.

How to check the shock absorber racks? There are 3 ways: visual, in work, after dismantling. Let us dwell on each individual.

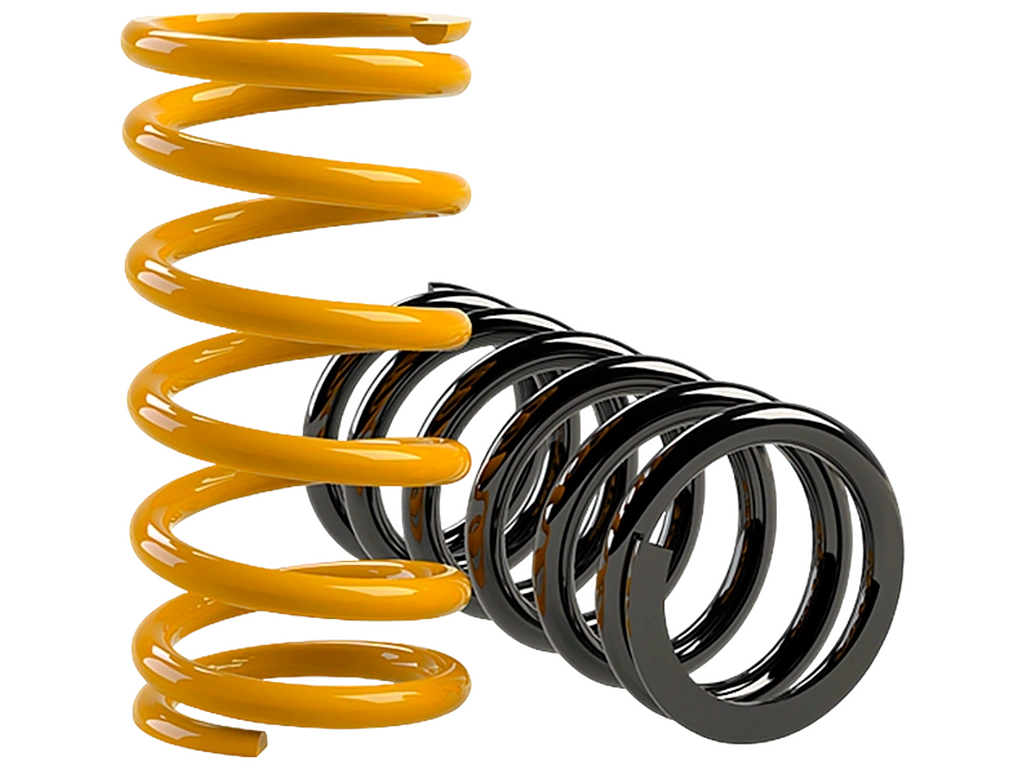

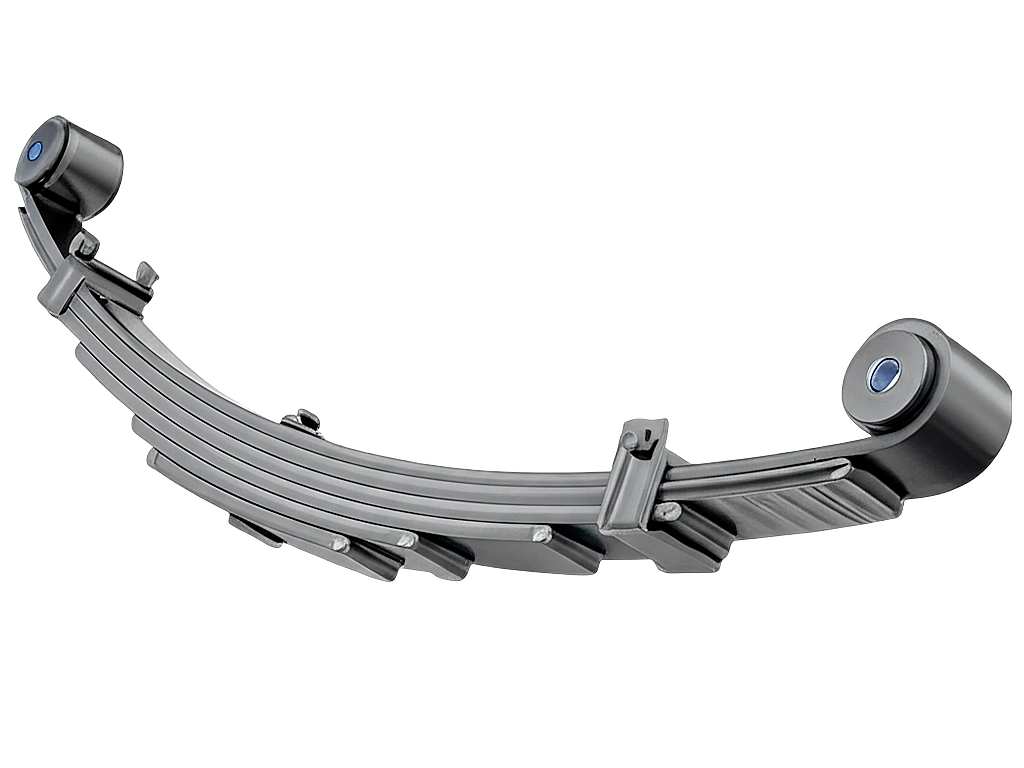

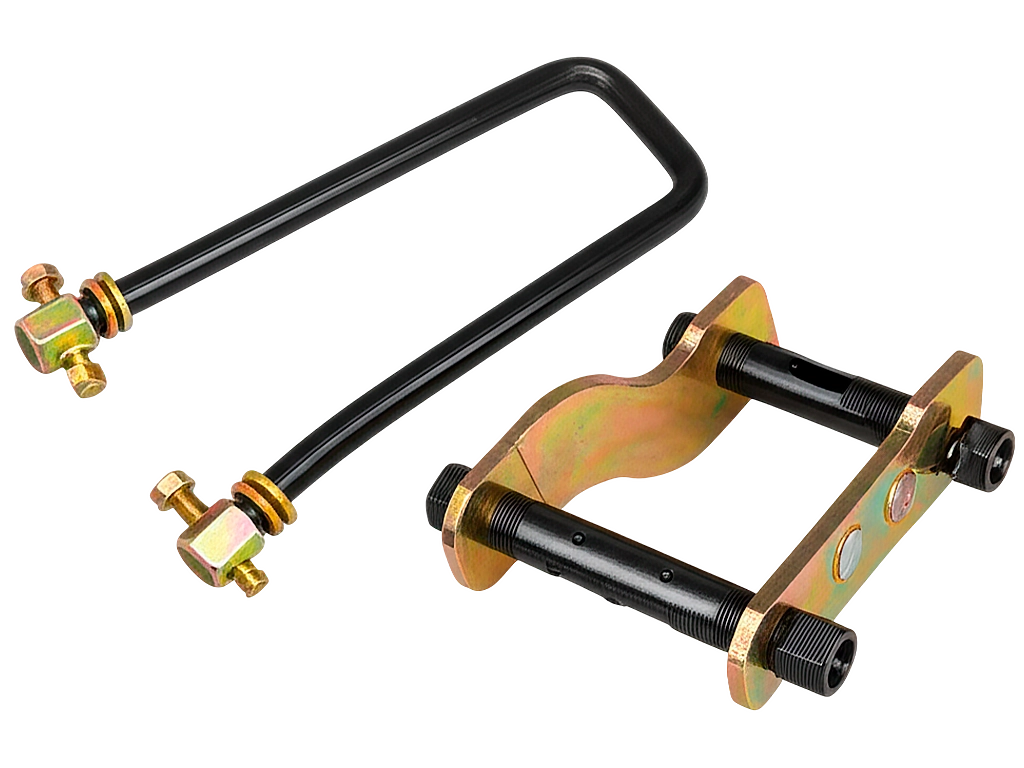

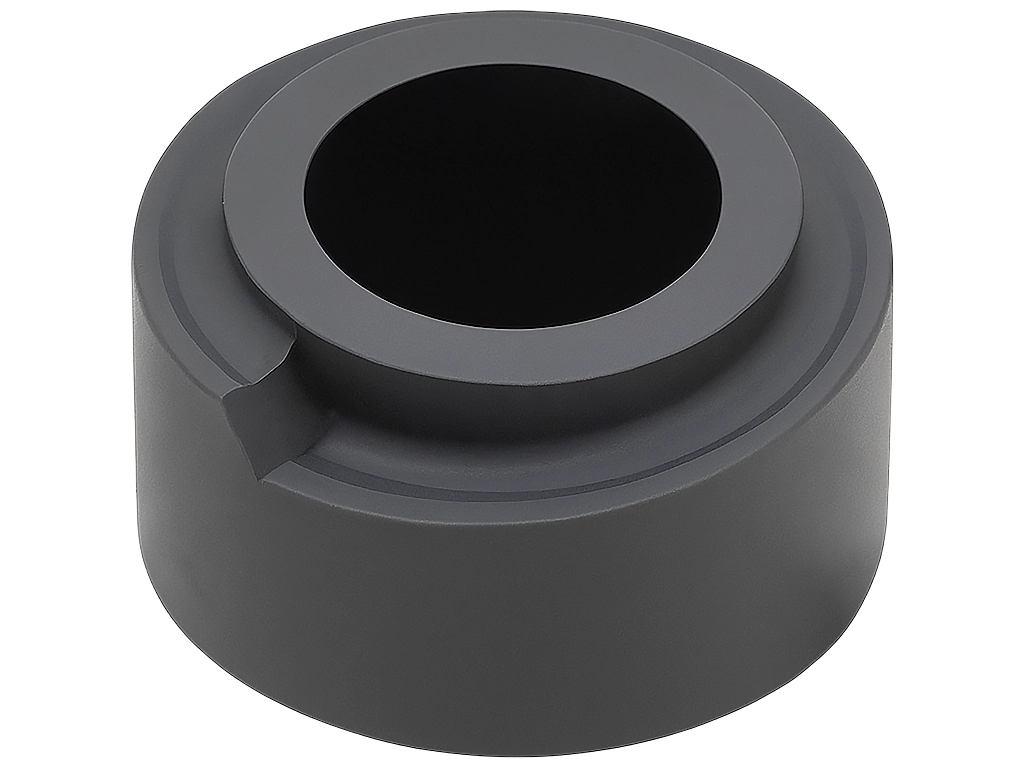

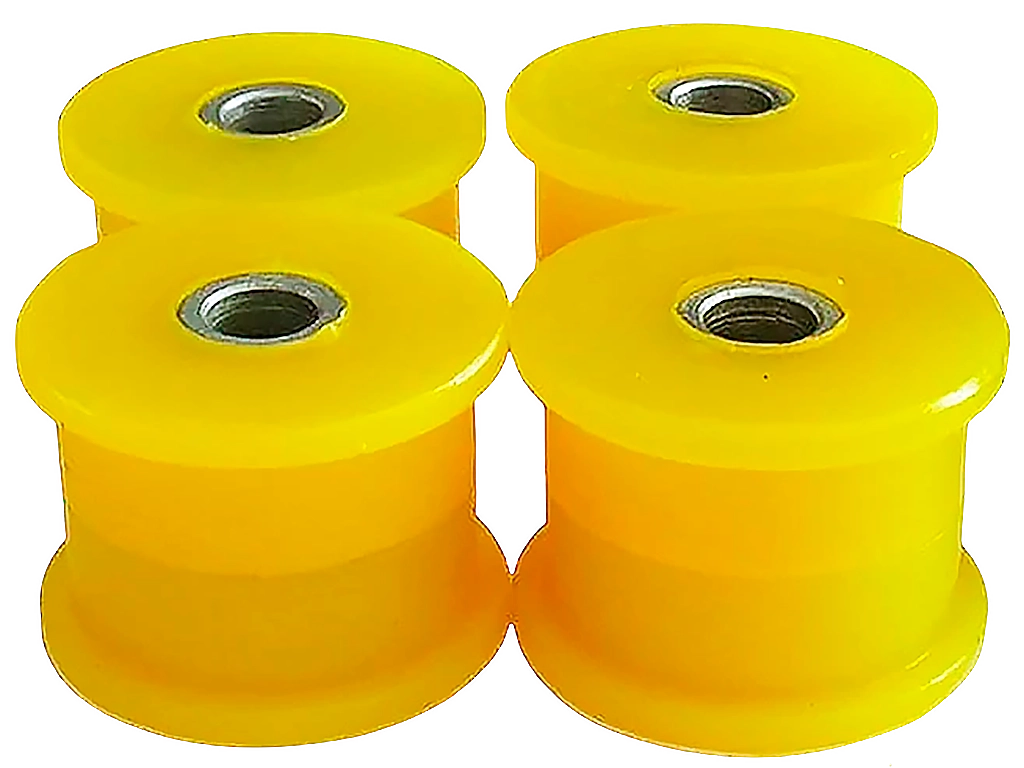

External inspection requires a minimum of cost, does not involve shooting wheels. Quality of work spring can be checked by body position - there should The springs themselves should be whole, do not contain traces of corrosion. When you are under the car, you should immediately pay attention to the condition of Silentblokov, bumper and anther. There should be no leakage, tearing and other defects.

The next stage of verification is the analysis of damping properties. You should press the wing of the car. If the body does not quickly return to the starting position, then the rack does not work properly. You can also try to swing the body, there should be no creak from the rack. You should also pay attention to the behavior of the car on the road. Problems with racks may indicate an increased inhibition path, deterioration of the ability to absorb inequalities on the road.

- poor resistance of the rack in order.The problem can be hidden in the leakage of the valve, wear of the spring. It is enough to replace these components for recovery.

- excessive resistance. This deficiency can be eliminated by removing part of the fluid.

- lack of normal compression resistance. Most often, this problem occurs when the valve is clogged. It is not necessary to change it, it is enough to perform washing. Replacement is only necessary in the presence of deformation. Wearing rod is also possible.